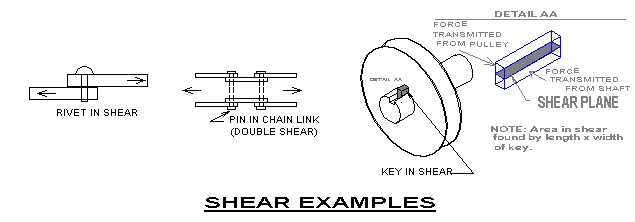

Shear Stress: Shear describes

the condition when parallel forces (planes) occur in opposing directions

such as scissors cutting paper, or a hole punch producing a sheared hole.

Shear strength is also important in mechanical fasteners, power transmission

couples, and manufacturing processes such as punching.

Shear stress is the applied force divided by the area in shear.

Lets look at some practical applications of how shear

stress occurs.

EXAMPLE PROBLEMS:

1. The Rivet shown in the diagram above is

1/4 inch in diameter and subjected to a 500 lb. load. Find the shear

stress in the steel rivet.

S = F / A(shear)

A = .7854 x (.25 in.)2 = .049 in.2

S = 500 lbs. / .049 in.2

= 10,204 psi

2. If the chain link shown in the

diagram is subjected to a load of 1000 lbs, and stress must be limited

to 25,000 psi. What should be the minimum diameter of the pin?

A(shear) = F / S ; = 1000

lbs. / (25,000 lbs. / in.2 ) = .04 in.2

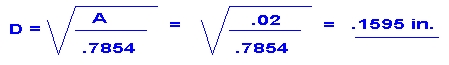

Note: The required total area in shear

is .04 square inches. Since the pin is in double shear, there are

two shear planes. Therefore the cross-sectional area of the pin is

half the calculated area in shear or .02 square inches.

3. Find the shear stress in the key show in the above diagram

if the shaft diameter is one inch and the torque is 1200 lb-in. The

key dimensions are .125 inch wide and 1 inch long.

As= w x L (of key) = .125 in x 1 in = .125 in2

T = F x d (Where d is the radius of the shaft); so F = T /

d

F = 1200 lb-in / .5 in = 2400 lbs.

S = F / As = 2400 lbs. / .125 in2 =

19,200 psi

BACK

HOME

NEXT