WEEK 1FLUID POWER

TODAY, THE FOLLOWING WILL BE COVERED:

+ NATURE OF THIS COURSE;

+ SYLLABUS FOR COURSE;

+ BASIC FOUNDATIONS OF FLUID SYSTEMS: TERMS, UNITS, RELATIONSHIPS.

Bold denotes IMPORTANT TERMS !

INSTRUCTIONAL OBJECTIVES:

A. Develop an understanding of some basic principles:

I. Pascal's Law

1. Pressure

a. head b. atmospheric c. gage

2. Force

3. Area

4. Density and Specific gravity

II. Mechanical and Hydraulic leverage

III. Basic Hydraulic Circuit

1. Hydraulic jack

2. Linear hydraulic circuit

B. Dimensional calculations - English and Metric systems

I. Units for:

1. Length

2. Area3. Volume

4. Pressure

5. Force

II. Example Problems for:

1. Head

2. Hydraulic Jack (lever)

3. Linear Circuit (sizing cylinder).

Homework Assignment: See Assignments Web Page.

C.

Standard Color Coding for Hydraulic Systems

BASIC TERMS, DESCRIPTIONS, UNITS, AND THEIR RELATIONSHIP.

TERM DESCRIPTION ENGLISH METRIC RELATIONSHIP

HEAD Height of a fluid column ft. m 1 ft. =.3048m

STROKE Length of rod travel in. mm 1 in.= 25.4mm

FORCE Thrust of a cylinder lbs. N 1 lb. =4.4482N

AREA Surface of a piston in.2 mm2

PRESSURE Force/Area lbs/in2 N/m2

or N/mm2

(NOTE: 1 N/m2 is also called a Pascal denoted by Pa.)

(1 PSI = 6895 Pa.)

(1 N/mm2 is also called a Mega Pascal denoted by MPa.)

(1 PSI = .006895 MPa.)

BAR (Average Barometric Pressure) 14.5 PSI = 105 Pa.

VOLUME

Area X Length(height): in.3

or GAL. (NOTE: 1 GAL. = 231 in.3)

or cubic foot ( 1 cubic foot = 1728 cubic inches)

or mm3

or cm3

or m3

or Liter

(NOTE: 1000 liters = 1 m3 )

( 1 liter = 1000 cm3 )

( 1 liter = 106 mm3 )

FACTORS AND PREFIXES

FACTOR PREFIX SYMBOL FACTOR PREFIX SYMBOL

1012 tera T 10-2 centi c

109 gigi G 10-3 milli m

106 mega M 10-6 micro u

103 kilo k 10-9 nano n

102 hecto h 10-12 pico p

10 deca da 10-15 femto f

10-1

deci

d

10-18

atto

a

EXAMPLE PROBLEMS:

1. Find the head pressure

at the base of the storage tank shown if

a) the

tank is filled with fresh water;

b) if

the 20ft. tank is filled with oil having a weight density of 56 lbs./ft.3

SOLUTION: P= gx h

a. Weight Density for the fluid = 56 lbs/ft3

b.

56 lbs/ft3 x 20 ft. = 1248 lbs / ft.2 x 1 ft.2

/ 144 in.2 = 7.78 psi

2. Find the maximum that can be lifted by the hydraulic jack.

FORCE @ HANDLE (FA) = 20 pounds; SOLVE FORFORCE AT ROD (FB)

CYLINDER 1 = 1/2 INCH BORE (PUMP CYLINDER)

CYLINDER 2 = 4 INCH BORE (WORK CYLINDER)

NOTE: BORE IS THE

INSIDE DIAMETER OF THE CYLINDER.

SOLUTION: WORK @ A = WORK @ B OR 20 LBS. X 12 " = FB X 2"

240 LB-IN = 2 X FB, THEREFORE FB=120 LB.

ALTERNATE SOLUTION: Sum the moments about point c.

FB(2 in.) = 240 lb-in

FB = 120 lb.

AREA OF CYL 1 = .7854 X .5 IN.2 = .19635 IN.2

AREA OF CYL 2 = .7854 X 4 IN.2 = 12.57 IN.2

P=F/ACYL 1 ; P=120 LB./.19635 IN.2 = 611.15 PSI

FCYL2

=P X ACYL2 = 611.15 X 12.57 = 7682.2 LBS.

3. Determine the size (bore)

of the cylinder for the system

shown

below.

SYSTEM PRESSURE = 8 Mpa;

CLAMP FORCE = 36KN

SOLUTION: A=F/P = 36000 N / (8 N/mm2) = 4500 mm2

A=.7854 X (D2)

D= (A/.7854).5 = (4500/.7854).5 = 75.69 mm

+ FLOWRATE, VELOCITY, AREA RELATIONSHIPS FOR LINEAR ACTUATORS;

+ TERMS, UNITS, RELATIONSHIPS;

+

REGENERATIVE CIRCUIT.

Normal Linear Circuit. Under normal operation, the piston velocity (Vp) during the extension mode for a hydraulic cylinder is dependent on the pump flow rate (Q) entering the cap side of the piston and the cap area (Acap) as shown in the general equation below:

Velocity = Flow Rate / Area

Velocity of the piston during the extension phase of motion, can be determined using the formula as shown below:

Velocity

of piston during extension in normal linear mode equation: Vpext

= Qpump

Acap

Similarly, the velocity during retraction is calculated as follows:

Velocity of piston during retraction in normal mode equation:

Vpret

= Qpump

Aan

The time required for a hydraulic cylinder to extend is dependent on

the Stroke (S) or linear displacement of the actuator and piston velocity.

The general equation

is shown below:

Time = Stroke / Velocity

To determine time during extension, the velocity during extension much be substituted into the equation. Similarly, to determine the time during retraction, the retraction velocity must be used.

Regenerative Circuit. Regenerative circuits are used

when it is desirable to rapidly advance an actuator into position to reduce

cycle time. When configured as

a regenerative system, cylinders can be advanced more rapidly than

in normal operation with the pump flow rate alone. In order to accomplish

regeneration, the fluid leaving the rod end of the cylinder is routed back

to the cap side of the cylinder to combine with the pump flow rate from

the pump as depicted in Figure 1 below:

Therefore, QTotal = Q Pump + Q Regenerative.

Solving for Q Pump: Q Pump = QTotal - QRegenerative

Remember that Flow Rate (Q) = Piston Velocity (Vp) x Area.

Substituting the appropriate areas, the equation for Qpump becomes:

Qpump = Q Total - Q Regenerative

Qpump =[Vp x Acap] - [Vp x (Acap - Arod)]

Factoring out Vp, the equation becomes:

Qpump = Vp (Acap - (Acap - Arod)

= Vp (Acap - Acap + Arod)

= Vp (Arod)

Therefore: To find the velocity of piston IN REGENERATIVE MODE, the equation below can be used.

Velocity of piston

during extension in regenerative mode equation: VpRegeneration

= Qpump

Arod

Note: Regeneration circuits are typically only used on cylinders having a single rod and only in the extending direction!

Next we will consider force during extension in

the regenerative circuit. Since both the capside and rodside

are pressurized at the same time,

the pressure in the system is constant and equal

on both the capside and rodside of the cylinder as shown in Figure 2 below:

Resulting force available on the external rod is the net force or difference

between the force on the capside and the rodside cylinder. Note that

even

though both sides are pressurized, the force on the capside will be

greater that the force on the rodside due to the cap area being greater

than the annular area.

Force in a regenerative circuit during extension of a single rod, double

acting cylinder is show in Figure 3.

Note: If (and only if) the

ratio of CAP area to ANNULAR area is exactly 2:1, equal speed and force

will result for a

regenerative circuit operating during extension AND a normal linear circuit

operating during retraction.

A typical complete regenerative

circuit in extension mode is shown in Figure 4 and retraction mode in Figure

5.

WEEK 3

THE FOLLOWING WILL BE COVERED:

+ Fluid Properties

+ WORK, POWER AND HORSPOWER;

+ Review FLOWRATE, VELOCITY, AREA RELATIONSHIPS FOR LINEAR ACTUATORS;

+ EXAMPLE PROBLEMS

Blue denotes important terms

DENSITY and SPECIFIC GRAVITY

MASS : Property

of a body of fluid that is a measure of inertia or resistance to change

in motion.

The term can also be used as a measure of the "quantity of fluid"

Note: In the Imperial System, the SLUG is used for MASS DENSITY (r).

Since m = F / a; the units = lbs / ft/sec2 = lb-sec2/ ft. Therefore 1 slug = 1 lb-sec2 / ft.

Typically we are more concerned with MASS DENSITY or SLUGS / cubic feet

Example: Suppose a hydraulic fluid has a weight density of 58 lbs / ft3

m = F / a = 58 lbs / 32.2 ft/sec2 = 1.8 lb-sec2 / ft OR 1.8 SLUGS / ft3

For the SI system, the unit of kilogram (kg) is used to denote MASS DENSITY.

The Newton (N) is the standard unit of Force and is defined as 1 kg - m / sec2

Example: A boulder has a mass of 5.75 kg, what is the force in N due to the earth's gravity?

Answer: F = m a = 5.75 kg x 9.81 m / sec2 = 56.4075 kg - m / sec2 = 56.4075 N

Note: On the earth's surface, acceleration

is assumed to be constant, and weight density or specific weight

is typically used. MASS DENSITY is crucial when designing hydraulic

systems for space craft.

WEIGHT DENSITY:

Weight density is defined as specific weight per volume.

In the Imperial system typical units would be lbs / ft3

In the SI system typical units are N / m3

SPECIFIC GRAVITY:

Specific gravity is a ratio of the density of a fluid compared to the density

of fresh water. Specific gravity

can be expressed as a ratio of MASS DENSITY OR WEIGHT DENSITY.

NOTE: The constant for fresh water (weight density) used as a standard is 62.4 lbs / ft3 in the Imperial system

For the SI System, the MASS DENSITY of fresh water is 1000 kg / m3

Therefore the weight density (g) = 1000 kg / m3 x 9.81 = 9810 N / m3

Example Specific Gravity Problem: Find the specific gravity of sea water if the SPECIFIC WEIGHT is 10.1 kN / m3

Answer: 10.1 kN/m3 = 10,100 N/m3 Sg = gsea

water / g fresh

water = 10,100 / 9810 = 1.02956

Week 3

I. Power, Torque and Mechanical Horsepower

Power = Work / time; Torque = Force x distance of moment arm;

HP = Power / Basic Unit of Horsepower (e.g. 746 watts, 550 Foot-lbs./sec, 746 N-m/sec.)

II. Horsepower in Hydraulic Systems

1. Fluid Horsepower

Generic Formula:

FHP = Pressure x Flowrate x C

(C = constant for converting to appropriate units)

English System: FHP = (P X Q) / 17142. Brake Horsepower

where: P = Pressure in PSI

Q = Flowrate in GPMMetric System: FHP = (P x Q) / 44.76

where: P = Pressure in mega Pascals (1 MPa = 1 N/mm2)

Q= Flowrate in LPM (liters per minute)

Note for computations, brake and torque horsepower use essentially the

same formula.

Brake howepower reflects the braking intensity or load placed on the prime

mover (e.g. electric motor).

The formula will be covered below.

3. Torque Horsepower

In hydraulic systems, indicates the horsepower available at a rotary

actuator:

Generic formula: THP = T x N x C (constant for converting appropriate units)

English System: THP = (T x N) / 63025

Where: T = torque in lb-in.

N = rpm

Metric System: THP = (T

x N) / 7121

Where: T = torque in N-m

N = rpm

4. Efficiency

Since no systems are 100% efficient, the formulae must me adjusted

to account for losses. Typically,

an efficiency of 80 to 85 % is assumed for hydraulic fluid horsepower.

Therefore the formula becomes: FHP = (P x Q) / (1714 x e)

for English system.

Similarly, efficiency must be included for the metric formula as well as

for THP formulas when

efficiencies are know. More attention will be given to efficiency

when pumps and actuators are covered.

Formulae and Example Problems - English and Metric systems for:

1. Flow, velocity and area

Flow rate (Q) = (V)elocity X (A)rea

Q = V x A; units must be compatible.

Example problem: A cylinder has a stroke (linear movement) of

of .25 meters and must extend in 5 seconds. Cylinder bore is 100 mm.

What is the required flow rate for the system?SOLUTION: A = .7854 x d2 = .7854 x (.1m)2 = .07854 m2

V = Stroke / time of extension

= .25 m / 5 seconds = .05 m / sec.

Q = V x A = .05 m / sec. x .07854 m2

Q = .003927 m3 / sec.

=.003927 m3 / sec. x 60 sec. / min. x 1000 liters/ m3

Q = 3.927 LPM (liters per minute)

2. Power and mechanical horsepower.4. Torque Horsepower.

Example problem: A forklift raises a 2000 lb. pallet 5 feet in 5 seconds.

What is the power output?

Solution: Power = Work / time = (2000 lbs x 5 feet) / 5 seconds = 2000 ft-lbs/sec

How much horsepower is required?

Solution: HP = Power / (Basic Unit of Horsepower)

HP = (2000 ft-lbs / sec) / (550 ft-lbs/sec)

HP = 3.643. Fluid Horsepower.

Example problem: A hydraulic system operates at 10 MPa pressure with

pump flow rate of 20 LPM. What horsepower is required for the electric

motor driving the pump assuming 85% efficiency?

Solution: FHP = (P X Q) / (44.76 x e)

Note the formula requires flow in LPM therefore units are compatible.

FHP = (10 x 20) / (44.76 x .85)

FHP = 4.47

Homework

Assignment: See Assignments Web Page.

THIS WEEK WILL BE DEDICATED TO PROJECT WORK.

+ ORGANIZING WORKSHEETS IN EXCEL

+ EXCEL EXAMPLES: DEALING WITH CIRCULAR REFERENCE

+ Introduction to systems and preparation

for Lab 4 (putting together what we have learned to date).

TOPICS:

+ Review SPECIFIC

GRAVITY

+ Review

WEIGHT DENSITY

+ Review

MASS DENSITY

+ Review

HEAD PRESSURE

+ VISCOSITY

+ VISCOSITY

INDEX

+ BULK MODULUS

NOTE: EXAMPLE PROBLEMS

WILL BE USED TO EXPLAIN THESE TOPICS.

RELATIONSHIP OF SPECIFIC GRAVITY, WEIGHT DENSITY, MASS DENSITY.

Sg = Weight Density of "X" / Weight Density of Water

= Mass Density of "X" / Mass Density of Water

Properties of fresh water will be used as a standard.

VISCOSITY

ABSOLUTE

KINEMATIC

SAYBOLT UNIVERSAL SECONDS

VISCOSITY INDEX FOR RATING THE STABILITY OF A FLUID

BULK MODULUS AND THE COMPRESSIBILITY OF A FLUID

LAB: SYSTEM SPECIFICATIONS FOR AN APPLEJUICE PROCESSING SYSTEM.

(NOTE:

This lab will incorporate virtually everything that has been covered thus

far in this class)

The

purpose of the lab is provide an application for system design, AND to

serve as a review for test one.

TEST ONE

TOPICS

+ BULK MODULUS

Example: Hydraulic feed for a milling machine.

+

VOLUMETRIC DISPLACEMENT (VANE PUMP)

Deriving the formula:

Vd

= Pi/2 (Dc+Dr) (e) (L)

Example problem for a variable displacement pump.

+

VOLUMETRIC DISPLACEMENT (PISTON PUMP)

Deriving the formula:

Vd

= D x A x Y x (tan O )

Example problem for a variable displacement pump.

+ EFFICIENCIES AND

RELATIONSHIPS

WEEK 8

TOPIC: PUMPS THEORY AND EXAMPLES (Video tapes)

Review UNIT 3 on Pumps from the following site:

http://64.78.42.182/free-ed/MechTech/hydraulics01/default.asp

Topics:

Conservation of Energy

Continuity Equation

Bernoulli's Principle

Pressure Losses Through Conductors

Conservation of Energy (Review)

Energy cannot be created nor destroyed

Three froms of energy related to incompressable fluid flow

Pressure Energy (PE)

Kinetic Energy (KE)

Elevation (Potential) Energy (EE)

Continuity Equation

Volume

Flow Rate in must equal Volume Flow rate out.

Qin = Qout

Q = A x V

A1 x V1 = A2 x V2

V2 = (A1 x V1) / A2

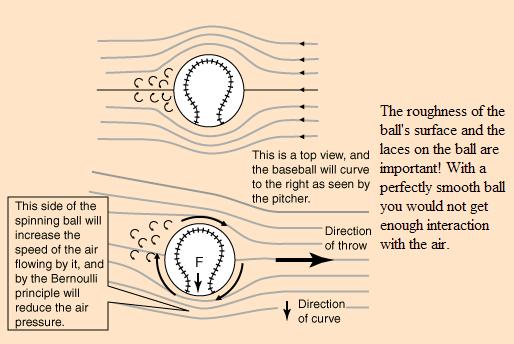

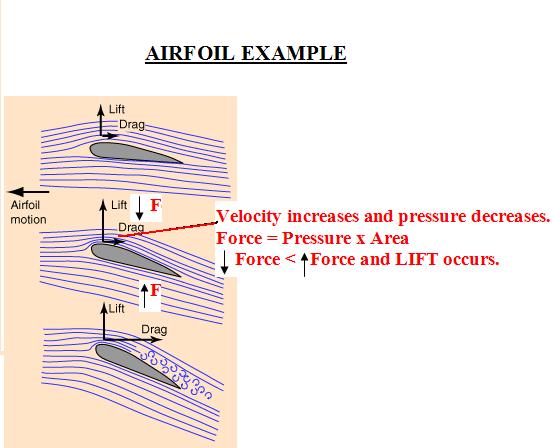

Bernoulli's Principle

When

the velocity of a fluid increases, the pressure exerted by that fluid decreases.

Curve of a Baseball Example

For an animation of why curve balls curve, click here

To view an animated air foil example, click here.Demo:: Take a sheet of paper, and tear a strip (approximately 1 1/2 inches x 11 inches)

Hold the paper strip under your bottom lip (lenghtwise facing from you).

Blow across the top of the strip of paper....what happens? Why?ROLLING CANS DEMO

FLOW THROUGH CONDUITS (PIPES, TUBING, HOSE)

Where:

A = Area

r = Radius

h = height or Elevation

P = Pressure

v = Velocity

Venturi Demo

Flow Example 1 : http://library.thinkquest.org/27948/bernoulli.html

Flow Example 2 (with Q,V,A plot: http://home.earthlink.net/~mmc1919/venturi.html#animation

Darcy's Equation

Pressure losses through fluid systems

WEEK 12 CONDUCTORS AND SIZING

Piping Selection Chart: http://www.onlinepipe.com/pipechart.html

Flexile Hose Types :http://www.hydraulicspneumatics.com/200/TechZone/HydraulicHoseTu/Article/True/6417/TechZone-HydraulicHoseTu

Flexible

Hose Sizes and Pressure Ratings (SAE)

Fundamentals of Pneumatics (tutorial

with video clips)

http://www.nfpa.com/Training-Pneumatic/

KEY EQUATIONS:

(P1V1)/T1 = (P2V2)/T2

CONSUMPTION RATES: CR = (atmospheric

pressure + gage pressure) / atmospheric pressure; Based on standard air,

atmospheric pressure is assumed to be 14.7 pisa for the English System,

101 KPa for the Metric System.

CR = (14.7 + gage pressure) / 14.7

Qr(cyliner) = (A x S x N x CR) / K Note: In the English System: A= in sq. S = in. N=cpm ; CR=compression rate; K = 1728

Qr (cylinder) = (A x S x N X CR)/ 1728

Qr(motor) = (Vd x N x CR) / K ; Note In the English system: Vd in cubed / rev; N = rpm; CR = compresstion ration; K = 1728

Qr(motor) = (Vd x N x CR) / 1728

SIZING RECEIVERS: (an example problem is also shown in your text)

Vr

= atmospheric pressure x (t) x (Qr-Qc) / (Pmax - Pmin)

t is the time the system is consuming air (usually the maximum

flow condition);

For the English system, using standard air and SCFM for Q the equation

is as follows:

Vr = [14.7 x (time in minutes) x (Qr - Qc)] / [ PSI(max) - PSI(min) ]

PRESSURE LOSSES DUE TO FRICTION: ( English System - assuming schedule 40, commercial steel pipe)

General equation for Delta P = c x L x Q2 / CR x d5

Specifically for commercial steel pipe, schedule 40, English system only.

Delta P = (0.1025 x L x Q2) / ( 3600 x CR x d 5. 31 )

Where 0.1025 = friction factor for commercial steel pipe (these coefficients

are experimentally derived

based on the type of conduit being used.

L = Total length of pipe + equivalent lenght for valves and fittings.

Q = flow in SCFM

3600 = Constant to convert units

CR = Compression ratio

d = pipe diameter in inches (use actual inside diameter for schedule 40

pipe).

POWER AND HORSE POWER (For adiabatic conditions which assumes no loss or gain of heat).

To determine the horsepower and power required to drive an air compressor, the following formulae can be used:

For the English System, Use:

HP = [ (Pin x Q) / (65.4)] x [ (Pout / Pin)0.286 - 1 ]

Where: Pin = inlet

atmospheric pressure ( psia)

Pout = outlet pressure (psia)

Q = Flow rate (standard cubic feet per minute)

Note: This is a variation of the formula used in the Norvelle text.

The 0.0286 constant is for air under adiabatic conditions.

for an explanation of the adiabatic process click

HERE

For the metric System to determine theoretical power (kW) use:

Power (kW) = [ (Pin x Q) / 17.1 ] x [ ( Pout / Pin) 0.286) - 1 ]

Where: Pin = inlet atmospheric pressure (kPa abs)

Pout = outlet pressure (kPa abs)

Q = flow rate (standard meters cubed per minute)

WEEK 15 FINAL EXAM

BACK INDEX PAGE