PURPOSE

This laboratory assignment will introduce

students to Automation Studio software and provide an opportunity

to observe the relationships between Force (F), Pressure (P), Area

(A)

and Flow rate (Q), Velocity (V), and Area (A) in a simple linear

hydraulic circuit. The bore and rod diameter for a

2:1 area ratio will first be determined for the given system pressure

and required force. Next, the required pump size will be

determine to obtain a cycle time of 12 seconds for the same circuit.

OBJECTIVES

After completing this laboratory, you should be able to do the following:

1. Determine the purpose and function of basic components in a simple linear hydraulic circuit;This laboratory evaluates two basic relationships in a basic linear circuit including Pascal's Law and factors affecting speed of an actuator.2. Identify ISO symbols and circuit components ;

3. Develop a working hydraulic schematic in Automation Studio;

4. Conduct a computer simulation of circuit operation;

5. Observe pressure differences (extending vs. retracting);

6. Determine the appropriate actuator size for bore and rod diameter assuming a 2:1 area ratio;

7. Determine the appropriate pump size in Liters Per Minute (LMP) to drive the hydraulic cylinder achieving a 12 second cycle time.

8. develop a concise technical laboratory report of your findings.

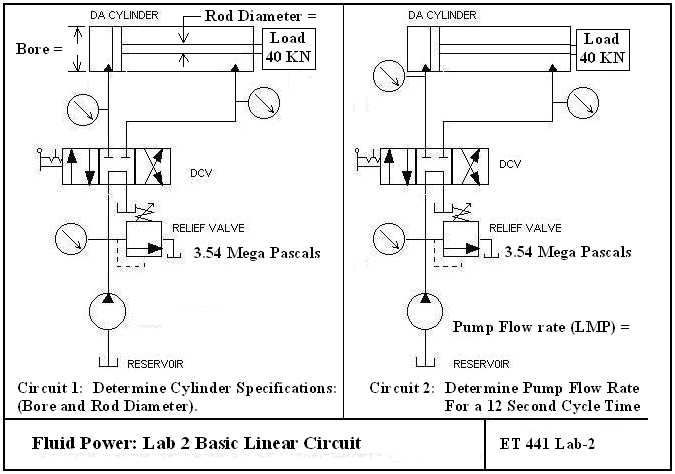

CIRCUITSComponents Required: Computer running Automation Studio; Unidirectional, fixed displacement hydraulic pump with reservoir; Relief Valve: Set relief valve to 500 psi. Directional Control Valve (4 way, 3 position, tandem center) Pressure gages Linear Actuator (specifications to be determined).

PROCEDURE: The following steps should be

taken in carrying out the execution of laboratory one. Take care

to follow

procedures as demonstrated by the instructor when constructing the

circuits in Automation Studio.

____ 1. Construct circuit one as show above in Automation Studio.

____ 2. Manually Calculate the required cylinder BORE and ROD DIAMETER; Record the calculated values in the chart below.

____ 3. Enter the calculated cylinder

parameters (cylinder bore and rod diameter) in Automation Studio by

clicking on the DA cylinder icon.

____ 4. Assume no inertia or friction for the actuator by entering 0 for each of the cylinder parameters.

____ 5. Adjust the relief valve for a minimum of 3.54 mega pascals.

____ 6. Run a simulation of the circuit,

check and record pressure during extension. (Note: The

loading conditions are assumed to be

during extension only. You must remove the load by setting it to

zero during retraction to accurately simulate pressures in the system).

Do this, and record the pressure during retraction.

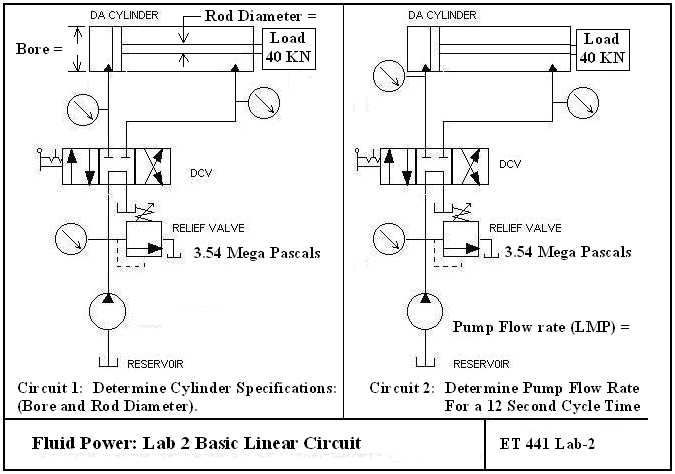

____ 7. Assuming a required total cycle time

of 12 seconds, calculate the required pump flow rate in Liters Per

Minute (LPM) assuming a stroke of 1200 mm.

Enter the calculated values in the chart shown below.

____ 8. Complete calculations for velocity during extension and retraction; Enter values in the chart below.

____ 9. Note: Automation cannot

accurate simulate time of extension and retraction due to differences

in processor speeds of various computers used.

____10. Analyze your calculated and observed data.

____11. Using

the format shown in the lab report guide, submit a formal written

lab report

by next class meeting or as requested by your lab instructor.

RESULTS (Example charts, create your own in Excel).

Cylinder Specifications Calculations:

Actuator Time Calculations:

Pump Flow Rate and Actuator Velocity Calculations: