Volume of Tank = Area x Height of Tank

Time to fill = Flow rate x elapsed time

PSIA = PSIG + 14.7

Head Pressure = .433 psi/ft x fluid head in feet

Purpose: The purpose of this laboratory exercise is to introduce the use and application of math-scripting as a function in LabVIEW. Math Script allows for embedding formulas or C+ type code as a sub-program and makes programming more efficient when calculations are needed. To illustrate this application, a fluid pumping station will be created, and time to fill the tank along with other variables will be calculated and displayed on the front panel.

Objectives: The objectives of this exercise are to allow

students to become familiar with the following:

Creating a Math Script structure

Creating INPUT variables

Creating OUTPUT variables

Writing formulas

Displaying required results

Procedures:

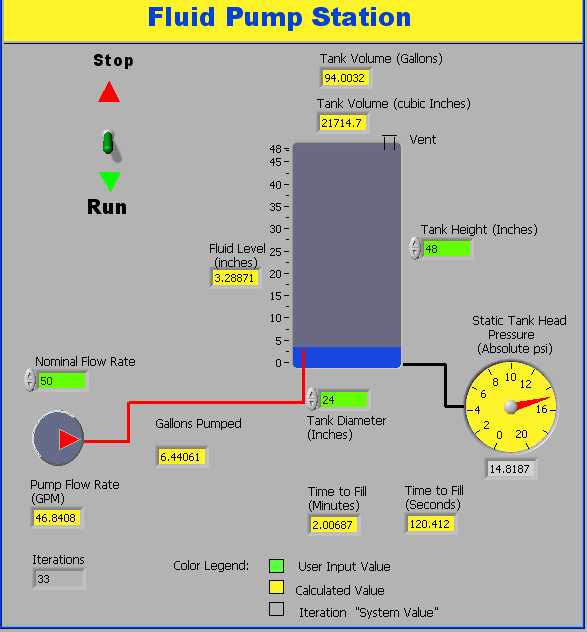

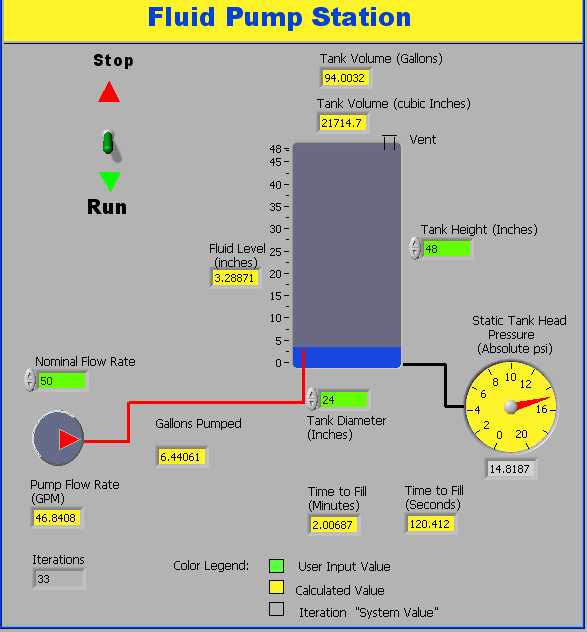

Study the system diagram shown in the page 3. Your system should calculate the following outputs based on given inputs. A table showing input variables and calculated variables is shown below.

Input Variables

Nominal Pump Flow Rate

Tank Diameter (inches)

Tank Height (inches)Calculated Variables

PSIA = (FH /12 * .433) + 14.7Pump Flow Rate (GPM): GPM = Nominal – (zero to 4 gallons per minute).

Note use a random number generator to simulate actual GPM.

GP - Gallons Pumped: Gallons pumped = Actual GPM x Elapsed time in

minutes.

TV – Tank Volume (cubic inches)

TVG – Tank Volume (gallons)

FL - Fluid Level (inches)

TTF -Time to Fill (minutes)

TTFS - Time to Fill (seconds)

PSI - Head Pressure (absolute PSIA) Note: Assuming water is being pumped, the static head pressure

can be found by the following formula:

General System Operation: Based on the nominal flow rate of the pump, the area of the tank, and height of the tank (shown in green), the VI should calculate and display the variables shown in yellow below. If the fluid level in the tank is equal to the vertical height of the tank, the system should automatically shut down. Note: Use a 250 ms wait function inside the while loop.

Procedures continued:

A demonstration of math script will be given in class. You will need to develop the block diagram for the corresponding front panel shown above. Note up to now you have been given both the front panel and block diagram. In this exercise, you will be required to develop your own. Note, it is advisable to hand calculate values to confirm your answers.

Submit a lab report in the usual required format.

Helpful conversions and formulae

231 Cubic inches = 1 Gallon

Volume of Tank = Area x Height of Tank

Time to fill = Flow rate x elapsed time

PSIA = PSIG + 14.7

Head Pressure = .433 psi/ft x fluid head in feet

Fluid Pumping Station Front Panel