BASIC STEPPER MOTOR CONTROL USING A PLC

PURPOSE: The purpose of this laboratory exercise is to

control the direction and speed of

a stepper motor using a PLC. Data Bytes will be used to define

the sequence bit pattern

for each respective step. Speed of the motor will be controlled

using a timer for delaying

between pulse output. Counters will be used to keep track

of the number of bit patterns produced

and the total steps generated

in both the forward and reverse direction.

OBJECTIVE: Write a PLC program to drive the pointer on the simplified measuring device

to 10 mm greater than the starting location, and then return to the original starting

point.

PROCEDURE: The following steps should be taken to carry out this laboratory exercise:

1. Define 4 data bytes corresponding to the

required step sequence bit pattern;

2. Use Q Byte (QB0) as the output BYTE

for controlling the motor;

3. Program an on delay timer to create a one

shot "clock pulse" from a counter at a time interval

of 20 milliseconds;

4. Use one counter to count step sequences

and a second counter to count total sequences;

5. Use the Move Byte function to move the

required data byte to QB0 depending on the

counter value being

used to count step sequences.

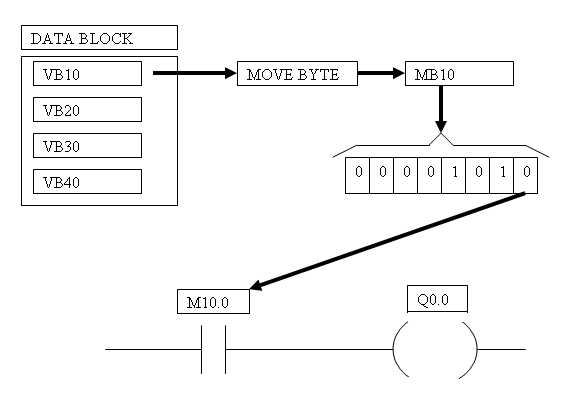

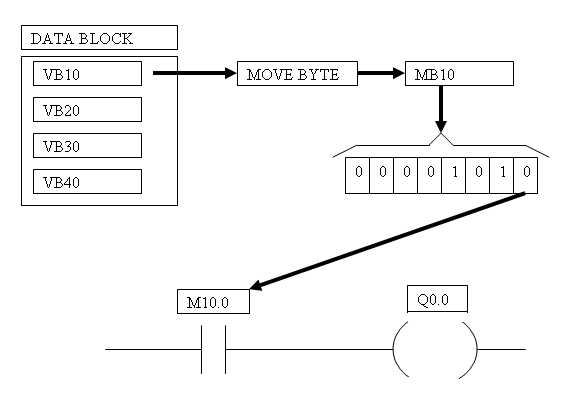

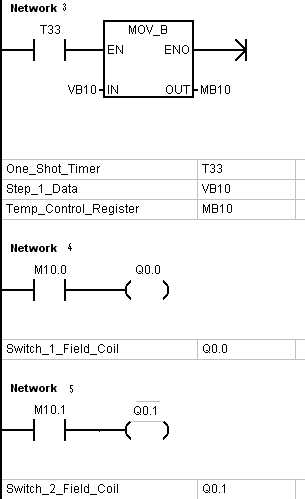

Note: An improvment in your program can be made by following the following method.

By using Memory Bytes (MB....i.e. MB10) rather than QB0, extra output bits can be reserved for

controlling outputs rather than the four field coils for the stepper motor.. Remember a BYTE = 8 bits, and

QB0 will consume all 8 bits of the output byte for addresses Q0.0 through Q0.7. Since only 4 bits

are actually required for controlling the stepper motor, 4 bits of QB0 would be "wasted". Therefore

to avoid this, simply MOVE the DATA BYTES (i.e. VB10 to MB10), then use discrete individual

bytes of MB10 to control the field coils of the stepper motor. A conceptual diagram and example

PLC Networks are shown below:

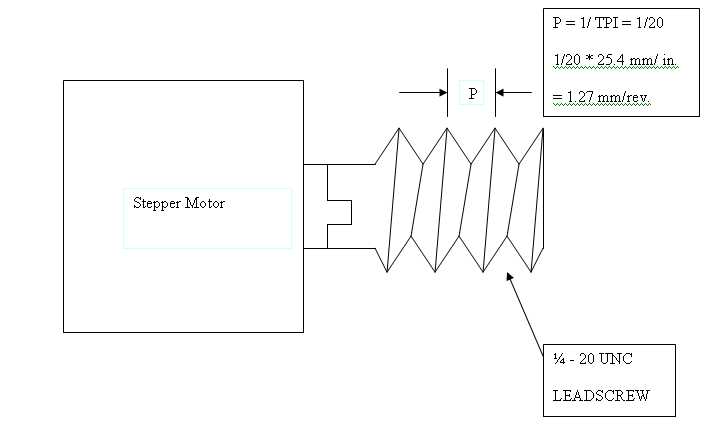

6. Write the program to generate the pulse

train required for the distance to be moved.

(Note: You will have

to determine the total number of revolutions required to equate to 10

mm).

The leadscrew attached

to the stepper motor is 1/4-20 UNC, and is a single thread.

Therefore, the lead is equal to the pitch = 1/20 inch per revolution.

!/20 in. X 25.4 mm/in. = 1.27 mm/rev.

7. Complete your PLC program and download to the simplified measuring station; run the PLC program.

8. Compare the finish point to the original

starting point on the motor shaft and determine

if any error occurs

(e.g. too few or to many steps generated).

9. Modify your program to compensate for any

error (if required) and be prepared to

explain why any modification

was necessary.

10.Submit a written laboratory report, following

the usual format.

SUPPLEMENTAL INFORMATION

The following four step in put sequence provides CW rotation as viewed

from then nameplate end

of the motor. To reverse the direction, step sequence is 1,4,3,2,1.

STEP SWITCH 1

SWITCH 2 SWITCH 3

SWITCH 4

1

ON

OFF

ON

OFF

2

ON

OFF

OFF

ON

3

OFF

ON

OFF

ON

4

OFF

ON

ON

OFF

1

ON

OFF

ON

OFF

SUPPLEMENTAL SUPPORTING DIAGRAMS

AND EXAMPLES

WIRING DIAGRAM

MOVE FUNCTIONS

EXAMPLE OF USING COUNTER WITH IF CONDITION (----| = = I |-----)

TO MOVE DATA

FROM A VARIABLE BYTE (VB10) TO OUTPUT BYTE (QB0).

NOTE: IF COUNTER 0 (C0) IS EQUAL TO 3, THEN THE CONTENTS

OF VB10 WILL BE

MOVED TO OUTPUT BYTE (QB0) AS SHOWN IN NETWORK 1 BELOW.

Description of operation: MOV_B

The Move Byte (MOV_B) box moves the input byte (IN) to the output byte

(OUT). The input byte is not altered by the move.

Operands:

IN (byte): VB, IB, QB, MB, SMB, SB, AC, Constant, *VD, *AC

OUT (byte): VB, IB, QB, MB, SMB, SB, AC, *VD, *AC

Description of operation:

DATA BLOCKS: YOU WILL NEED TO CREATE DATA BLOCKS TO STORE

THE CONTENTS OF

THE BIT PATTERNS REQUIRED TO INDEX THE STEPPER MOTOR. ONE BLOCK

WILL BE REQUIRED

FOR EACH BIT PATTERN AS SHOWN BELOW:

//

//DATA BLOCK TITLE COMMENTS

//

//Press F1 for help and example data block

//

VB10 10 // DATA FOR FIRST STEP SEQUENCE

(BINARY 1010)

VB20 9 // DATA FOR SECOND STEP SEQUENCE (BINARY

1001)

VB30 5 // DATA FOR THIRD STEP SEQUENCE

(BINARY 0101)

VB40 6 // DATA FOR FOURTH STEP SEQUENCE (BINARY

0110)