ET 472 FINAL EXAM

Purpose and System Operation

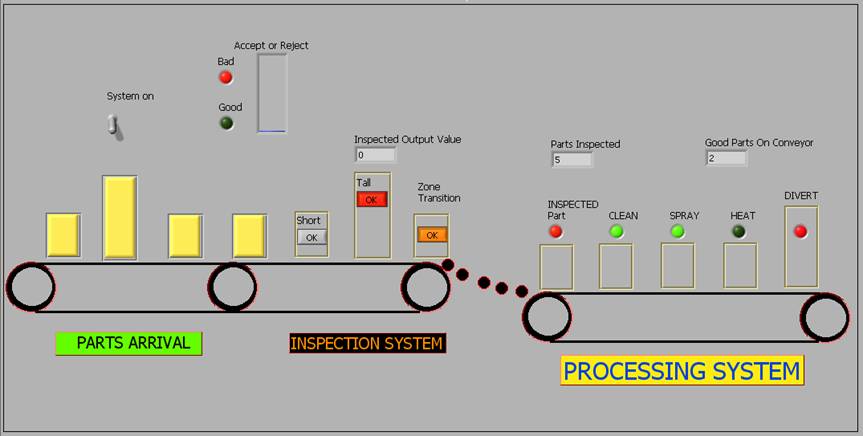

The purpose of this project

is to develop an inspection and processing system similar to the exercise

completed for laboratory number 2. However, for the final exam, LabVIEW will be

used rather than a PLC. The system

should inspect arriving parts for either short (good) or tall (bad) as they are

carried through the inspection portion of the system. After inspection, parts will pass through a

Zone Transition Sensor indicating that a part is present. If a good part is detected and the zone

transition sensor is activated, a logical one will be output for tracking. Similarly if a bad part is present and the

zone transition sensor is activated, a logical 0 will be the output for

tracking. If the zone transition sensor

is not activated, a logical 0 will also be the output indicating that no part

was physically detected on the conveyor system (this is the system

default).

Good Parts

When

good parts are processed through the system, a shift register will track the

parts inspection result and process at the downstream stations as follows: If a good part is detected, then the part

will been shown as good at the inspected parts station, and processed through

the clean, heat, and spray stations. The

divert station will be not be activated, thus allowing good parts to continue

straight through the system.

Bad Parts

When

bad parts are processed through the system, the shift register will track the

parts inspection result as a logical 0, transfer the bad parts through the

clean, heat, and spray stations (using no resources) until the divert station

is reached. At the divert station, parts

will be pushed off the system to a spur conveyor for sorting, reprocessing, or

scraping. Note: If no parts are present

on the system (the zone transition sensor is not activated) then the system

default will assume a bad part is present.

Requirements

The following requirements

must be met to obtain credit for the exam.

1. Complete a LabView Sub VI for the arrival and inspection

portion of the system. The Sub-VI should

process as shown in the system diagram and as demonstrated in class. Set the timing of the Sub-VI to 500 ms.

2. Create a LabView main VI to track the parts through

the system and control operations at downstream stations as described

above. The main VI should perform the

operations as shown in the diagram below and as demonstrated in class. Set the mail VI to run at 1 second.

3. Complete a written report in the same format as the

usual lab report. The report must

include the following:

a. Abstract 10

Points.

b. System requirements.

5 Points.

c. Symbols Chart

10 Points

d. Sequence Chart

15 Points

e. System Diagram

(Front Panel and Block Diagram)

30 Points

f.

Explanation of

system operation (in detail). 30 Points.

4.

NOTE: THE EXAM WILL BE DUE ON

EVENING OF THE EXAM. YOU MAY SUBMIT THE

EXAM EARLIER!

ET 472 FINAL PROJECT- EXAM SYSTEM

DIAGRAM