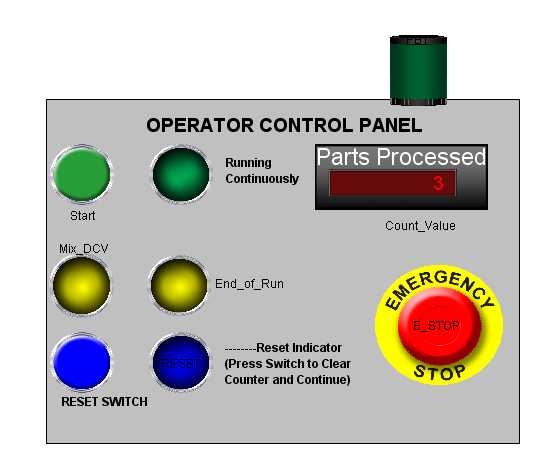

FIGURE 2: CONTROL PANEL LAYOUT

Pre-lab assignment

A demonstration will be given of a SFC program in class along with the procedure for developing a SFC

control program. Study your notes, and be familiar with the SFC user's manual (available in the help menu in Automation Studio).

Procedure

The following tasks should be completed in order to carry out this laboratory assignment:

1. Study the system requirements, and develop a control sequence table of tasks.

2. Identify the required variables, and create the associated tags.

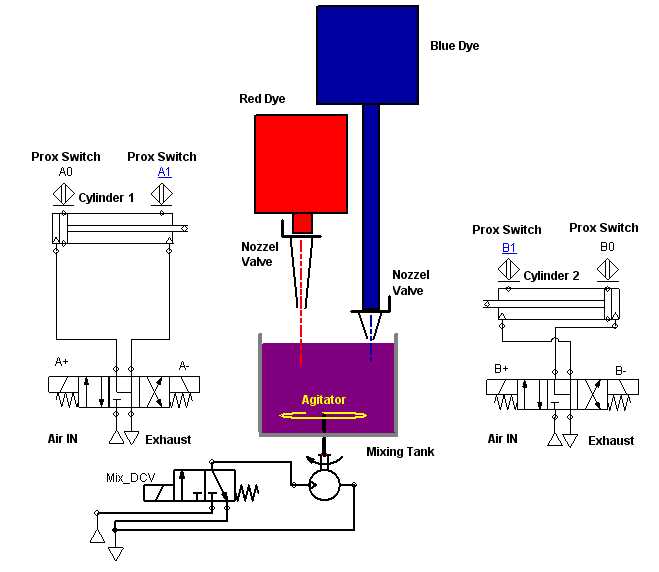

3. Develop the pneumatic schematic shown in Figure 1.

4. Create an HMI control panel as shown in Figure 2.

5. Develop a SFC control program.

6. Simulate the system to verify the SFC program functions correctly.

7. Develop a wiring diagram for PLC interface.

8. Provide a documented SFC program listing.

9. Complete a written report using standard format with a detailed explanation of how the system is controlled.