IONIC

COVALENT

METALLIC

VAN DER WAALS FORCES

UNIT CELL

LATTICE STRUCTURE

BCC

FCC

HCP

DISLOCATIONS

VACANCIES

INTERSTITIAL

GRAIN SIZE

GRAIN BOUNDARIES

SLIP

ALLOTROPIC

RECRYSTALLIZATION

INTRODUCTION: In Module 1 we

looked primarily at some mechanical properties of materials including the

plastic deformation of materials, the relationship between stress and strain,

and external loading. In Module 2, we will begin looking at the atomic

structures of materials and what makes materials behave the way they do,

why some are better conductors of heat than others, why some are brittle

while others are ductile, and so forth.

This module will focus mostly on the metals

group. Polymers will be covered in Module 4.

There are literally thousands of materials available however they can be divided into 3 major categories:

METALLIC

CERAMIC

POLYMERIC (INCLUDING WOOD)

These groupings are made because of the bonding forces (which depend on the atomic arrangement) are similar within a group. As we look deeper into the bonding forces, the reasons for varying properties such as harness, toughness, conductivity and strength can be more easily understood. First we need to review some basic atomic theory.

ATOMIC THEORY

The nucleus of the atom is made up of positively charged protons and neutrally charged neutrons. The nucleus makes up most of the weight of the atom, and elements can can be categorized by atomic weight. However, Atomic number determines the properties and characteristics of materials. So, what is the atomic number? It is simply the number of protons in the nucleus. The diagram below shows a simple model. Notice that the nucleus is positively charged and made up of "big protons and neutrons". But, this nucleus is surrounded by electrons that are negatively charged. An atom in the free state must be electronically neutral. Thus, the number of electrons surrounding the nucleus must equal the number of protons in the nucleus...this is the atomic number.

The number, arrangement, and spin of the electrons determines the kind of atom and its characteristics such as crystal forms, melting points. When shells are filled, the atom is stable; however electrons that are in unfilled shells are know as valence electrons and are largely responsible for the behavior of the element. Partially filled shells may give up or receive (accept extra electrons) or may share them with other atoms. The manner in which this "stabilization is reached determines the type of bonding. The period table arranges the elements in rows numbered from 1 to 103. Why this number? What is it? The atomic number is simply the stabilized number of electrons and protons. For example, Hydrogen (H) has one proton and one electron; Helium (He) has two electrons and 2 protons....all the way up to Lawrencium (LR) which has 103 electrons and protons. The periodic table in your text also shows classifications of metals by characteristics. In a complete period table, the atomic weight is also shown for each element.

NOTE: REFER TO YOUR TEXTBOOK ON PAGE 18

OR CLICK HERE TO GO TO THE

ONLINE

PERIOD TABLE.

.

As mentioned previously, materials are typically divided into 3 major simple classes: metallic; ceramic; and polymeric. These groupings are made because of the bonding forces which depend on the atomic arrangement are similar within a group. As we look deeper into the bonding forces, an understanding of the reasons for varying properties such as hardness, toughness, conductivity, and strength can be seen.

BONDING: When shells are filled, the atom is stable; however, electrons that are in unfilled shells are know as valence electrons. These valence electrons are largely responsible for the behavior of the element. It should be noted that metals are characterized by an ability to give up electrons. Partially filled shells mean that electrons may be given up, accepted from other atoms, or may share them with other atoms. The manner in which this "stabilization is acquired determines the type of bonding. There are four types of bonding:

* IONIC

* COVALENT

* METALLIC

* VAN DER WAALS FORCES

IONIC: When an element gives up or receives an electron in its outer shell an ION is formed. If the element gives up an electron, it is then left with at net + 1 charge, and is called a POSITIVE ION. An example of ionic bonding can be seen between lithium and fluorine:

Ionic bonding accounts for many common liquids and solids such as NACL, AgCL, MgO.

Characteristics of materials with ionic bonding include:

Medium - High Strength

Hard but Brittle

High Melting

Electrically Insulating (because all charge "transport" must occur through

ION movement

COVALENT BONDING: This type of bonding occurs from sharing of valence electrons (electrons in the outer shell). Remember that the nuclei is POSITIVE (+), therefore, if electrons (-) are shared by adjacent nuclei, the result is a VERY strong bond.

Characteristics of materials having a covalent bond include:

High Strength

High Melting Point

Brittle

Electrical Conductivity Depends on Bond Strength (e.g. tin to diamond)

METALLIC BOND: A common characteristic of metallic elements is that they contain only 1, 2, or 3 electrons in their outer shell. Since there are fewer electrons, the bond is relative loose to the nucleus. When the outer shell (or valence) electrons approach each other's adjacent orbit, the electrons may be "forced out of natural orbit". This results in positive ions being formed. These floating electrons form a "cloud" of shared valence electrons, and electron movement can occur freely. This is why electrical and thermal conductivity is high in metals. However, metals crystallize into close paced lattices. We will discuss lattice structures in more detail later in the module. Metals make up over three fourths of the elements and have the following common characteristics

Metals make up over three fourths of the elements and have the following common characteristics:

Ability to form positive ions through donation of electrons;

Have a crystalline as opposed to amorphic structure;

Have excellent thermal and electrical conduction;

Have varying degrees of luster and reflectivity.

VAN DER WAAL BONDS (FORCES):

This bonds are weak bonds are found in neutral atoms such as inert gases.

Molecules are linked together through weak positive and negative attraction.

some parts of the molecules are more positive than others. This type

of bonding is of little interest in metals except for very low temperatures.

However; it is much more important in polymers.

ATOMIC PATTERN ARRANGEMENT: Rather than describing the billions of particles that make up the grain structure, it is easier to look at the basic "building blocks" or atomic arrangement that occurs in materials. In metals this basic building block is called the unit cell. In polymers it is referred to as a "mer". This module will focus on metals.

When metals change from a liquid to a solid,

grains are formed. This is referred to as grain growth.

The process begins with the atoms arranging themselves into geometric patterns.

There are six patterns that are formed in different types of metals:

Face Centered Cubic (FCC)

Body Centered Cubic (BCC)

Hexagonal close packed (HCP

Cubic

Body Centered tetragonal

Rhombohedral

The most common are the FCC, BCC and HCP. A two dimensional representation of this three types is show below.

Iron has a unique characteristic in its ability to change from BCC at room temperature to FCC at elevated temperatures and back to BCC at critically high temperatures. This ability to change states is referred to as allotropic. Refer to your textbook, page 21, figure 1.11.

Steel is more easily deformed at elevated temperatures because it changes from a BCC to a FCC structure. Lets look more closely at the general characteristics associated with BCC, FCC, and HCP structures.

BCC - Body centered cubic structures, are more difficult to deform due to the additional atom being present at the center of the structure. However, it is a catch-22.....also more slip planes are formed.

FCC - Face centered cubic structures are generally more easily deformed simply because there is no common atom in the center of the cubic structure. As grains grow, more slip planes are created. However, considerable force is still required to cause deformation. This is really what occurs when steel reaches its yield point.

HCP - This structure shape has fewer planes for orientation and slippage however, materials having this atomic arrangement tend to be more brittle.

Crystals (grains) depend on:

1. Lattice type

2. Inter atomic forces

3. Spacing between atoms

4. Density of atoms themselves

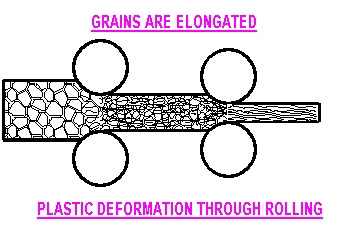

NOTE: During elastic deformation, the lattice structure

is shifted, stretched, and distorted, BUT RETURNS to the materials original

form. With plastic deformation, atoms change positions

and slip past one another because the atomic bond is broken.

Strength of a material also depends on crystal imperfections, alloying agents, and impurities. The diagram shown below shows examples of these factors.

There are 3 major classes of materials

Metals

Ceramic

Polymeric

Four types of atomic bonding exists

IONIC

COVALENT

METALLIC

VAN DER WAALS FORCES

Metals are made up of three basic crystal structures (UNIT CELL) types

BCC

FCC

HCP

Crystals grow to form grains, grains interfere during growth to form

boundaries.

Crystals are not perfect

-- have imperfections

Dislocations

Vacancies

Impurities

Inclusions

Interstitials

Material Properties depend on

Crystal

lattice

Grains are distorted

by boundaries.

Grain size is affected by temperature

Nature of defects

Some materials

have the ability to go through and allotropic

change

Iron (the base element in steel) is one of those materials.

Deformation may be elastic or plastic

Elastic deformation

- lattice structure is distorted but reorients

Plastic Deformation

occurs by slip along lattice, atomic bonds

are broken

Hardening may occur during plastic deformation

Results from entanglement of dislocations and grain boundaries

Can be eliminated by recrystallization at

elevated temperatures.

NOTE: USE OF HEAT TO ACHIEVE DESIRED PROPERTIES WILL BE COVERED

IN MODULE 3.

2. Would covalent bonded materials make good heating elements? Explain.

3. Draw and label an atomic model for tin showing the number of electrons in each shell.

4. How many valence electrons are there in problem 3?

5. Draw a diagram showing the phases of transition from liquid to solidification

in iron..from unit cell to grain boundary

formation.

6. Briefly discuss how current "flows" through a piece of copper wire.

7. Why is steel stronger at room temperature as opposed to elevated

temperatures above 1700 deg. F ? Hint:

Include an explanation of the term allotropic

in your response.

8. Of the 100 + elements, which are classified as heavy, brittle

metals? Hint: Locate a periodic table that breaks

down the classes of the elements. You

might want to consider the web for this.

9. Briefly explain how plastic deformation occurs in metals.

10. Explain the probable deformation characteristics of magnesium based

on its crystalline structure.