ET 449 ADVANCE TOOLING AND PROTOTYPING

Semester Project

A semester project is required for each lab section.

The project will be a group effort with equal participation from each student.

Team members will evaluate the success of the group and the contribution

of each individual team member. The project will consist of program

development for a 3D assembly consisting of a minumum of 6 components (excluding

hardware). Each group will create a working model and a production

plan and production run for an advanced prototype of sufficient complexity.

A complete set of documentation is required including but not limited to

the following:

1. Set of working

drawings produced to scale on CAD

2. Prototype

Development

3. Complete Documentation

of CNC Programs

4. Setup Procedure

for production

5. Program Verification

6. Tooling and

fixture design and fabrication

7. Prototyping

8. Production

Plan including OPERATION AND ROUTING SHEETS

9. Project presentation

and demonstration of working model.

PROPOSAL FORMAT (2 PAGES)

Some ideas for the semester project include the following. Note design, fabricate, assemble, and test one of the follwing working models or mechanisms.Statement of the problem

Objectives

Sketches

Bill of Materials

Procedures

Production plan (flow chart)

1. Stirling

Engine: Click here

for an animated example.

2. Compressed

air engine (not a Root's). Click

her for an animated example.

3. Hydraulic

Pump. Click here for

animated example.

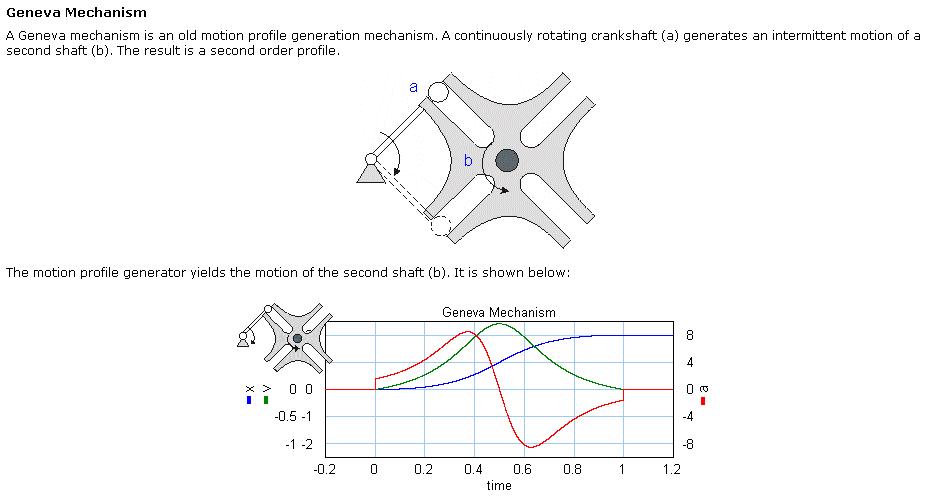

4. Geneva cam

indexing unit

5. Ball cam indexing unit

Source: http://www.20sim.com/webhelp4/Toolboxes/mechatronics/Cam_Wizard/CamMotionProfiles.htm#Geneva_Mechanism

6. Rachet and paw indexing unit

7. Cam

and Follower System at work within an Internal Combustion Engine

Source: http://www.ul.ie/~kirwanp/examplesofsystemsinuse.htm

8. Universal joint with drive coupling

Other examples of mechanisms can be found at: http://www.flying-pig.co.uk/mechanisms/index.html

http://www.ul.ie/~kirwanp/index.htm

http://www.cs.cmu.edu/~rapidproto/mechanisms/examples.html#toc

http://www.keveney.com/Engines.html

ET 449 Final/Project Format {250 Points Total}

PART A: WRITTEN {150 Points Total}:

Weights are shown in brackets, sub-weights in parentheses.Cover: Letter of Transmittal [20]

I. Statement of Problem [10]

A. Background and Requirements (5)

B. Objectives and Deliverables (5)II. Procedures [10]

III. Methods of Production [20]

A. Operations (5)

B. Tooling Requirements (5)

C. Feeds and Speeds (5)

D. Set-Up Requirements (5)IV. Results [25]

A. Description of Outcomes (5)

B. Description of Deliverables (5)

1. Models and Drawings (5)

2. Tables (Feeds/Speeds, Tooling, Set-up Sheets (5)

3. Photos and/or Renderings (5)V. Appendices (Exhibits of B1, B2, B3) [60 (20 points each)]

VI. References (APA format) [5]

PART B: PRESENTATION and DEMONSTRATION {100}

I. Presentation [50]

Note: For the presentation (Power Point), highlight the major sections of the

written report.II. Demonstration [50]

NOTE: YOUR MECHANISM MUST WORK!

Device will be demonstrated and tested. Each individual or team project will be coupled to an electric gear motor to verify operation of the mechanism(s).