ET 449: ADVANCED TOOLING AND PROTOTYPING

Week Topic Lab .

1 Optimizing Tool Paths for Production Simple Sub-assembly

2 High Speed Machining Sub-assembly rework

3 Lathe Operations External Threaded Shaft

4 Mill Operations Internal Threads

5 Fourth Axis Machining Positional Indexing

6 Full 4th Axis Machining Impellor or Gear

7 3-D Machining Simple Mold

8 Lazer Machining I.D. Tag or License Plate

9 Semester Project Planning Reverse Engineering and Parametric Design

10 Production Planning Group Project Work

11 Production Machining Group Project Work

12 Advanced CAM Operations Group Project Work

13 Advanced CAM Operations Group Project Work

14 Advanced CAM: Complex Surfaces Group Project Work

15

Final Exam

Lab Clean Up

Week 1

Introduction

Syllabus

Scope of Course

CNC Basics and SurfCam review

FEEDS AND SPEEDS

In general, referenced speeds and feed data are

for beginning points. Adjustments

may be necessary to compensate for the variables

above. Make sure referenced

data matches the type of operation and variables

show above as closely as possible.

SPEED CALCULATIONS:

RPM: GENERAL FORMULA:

RPM = CS / CIRCUMFERENCE

ENGLISH: RPM = FT. x 12 in. x

1 REV

Min. Ft

px D

METRIC: RPM = m x

1000 mm x 1 REV

min.

m px

D

NOTE: D =

DIAMETER:

FOR TURNING, D = DIAMETER OF STOCK

FOR DRILLING, REAMING, MILLING, D = DIAMETER OF TOOL.

FEED RATES:

TURNING: Refer to Tables for Turning:

General Recommendation

for low carbon steel: .007 -.010 in. per revolution (.25 - .4 mm/rev)

is used for roughing.

Finishing feeds are .001 - .003 in. per revolution (.07 - .12 mm/rev)

MILLING: Fr = N x T x RPM

where: N = Number of Teeth

Fr = Feed rate in IPM (or mm per minute for metric)

T = Feed per Tooth per Revolution

RPM = Revolutions per minute = CS/Circumference

MACHINING TIME:

LATHE: MT = LENGTH / (FEED X RPM); MT = L / (F X N)

MILL: MT = LENGTH / (FEED RATE); MT = L / ( fr )

MAKE SURE APPROPRIATE

TABLES ARE CONSULTED FOR MATERIAL

AND CUTTING TOOLS

BEING USED.

NOTE: THERE ARE TWO TYPES OF MILLING:

UP MILLING (CONVENTIONAL MILLING) - Chips are carried

away from the base stock.

Down Milling (Climb Milling) - Chips are carried into the base stock.

In general, UP

Milling is recommended for older equipment and lower horsepower

machine tools, and less

rigid setups. In climb milling there is a tendency for the cutter

to "climb over the work"

if the setup is not rigid.

Post processing procedures

Fixturing and Tooling considerations

Set Up Sheets and Operator Procedures

HAAS VF-1 Introduction

Controller

Layout

Navigating through MENUS

Setting Workplanes G54

Setting Tool Offsets

File Importing

Graphical Simulation

ASSIGNMENTS

Review the HAAS

controller layout

Navigating through MENUS:

Note: Visit the HAAS website and review the controller layout.

Complete all necessary

preparatory work for lab one (i.e. complete parametric mode, dwg, dxf,

i.d. tooling, assign tool number).

Lab 1 Prep work : TO

GO TO LAB 1 CLICK HERE.

CYCLE TIME

REDUCTION AND OPTIMIZATION

NOTES ON NEXT LABS 3,4,5.

The following illustraions show the logical

progression of steps to produce a fixture (Lab3), thread milled hub (Lab4),

and

hexagonal flats cut using the 4th axis (Lab5).

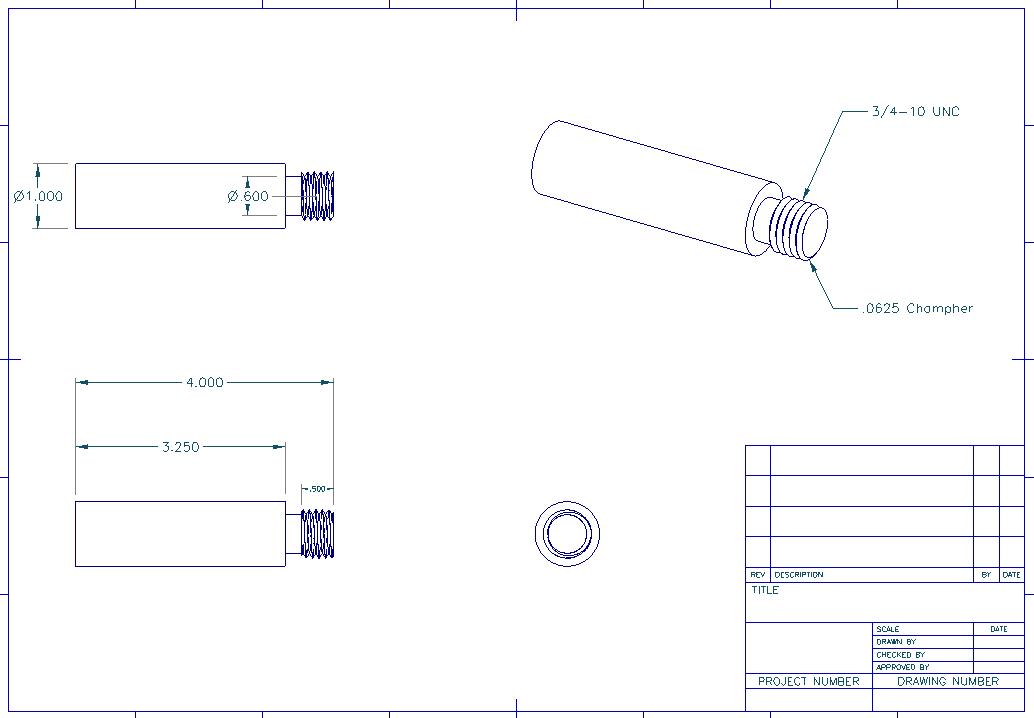

LAB 3: MACHINE A 1 INCH DIAMETER THREADED SHAFT TO BE USED AS A MOUNTING FIXTURE.

LAB 4: MACHINE A 3 INCH DIAMETER HUB BY THREAD MILLING THE CENTER HOLE.

LAB 5: MOUNT THRADED HUB (LAB4) ON THREADED SHAFT (LAB3)

LAB 5 CONTINUED: MILL 6 FLATS TO FORM A HEXAGONAL HUB USING 4th AXIX

POSITIONING METHOD

Purpose: This exercise will cover the basic procedures for Outside Diameter (O.D.) turning and external threading operations in OneCNC. File importing, coordinate systems, CNC options, tool selection, and toolpath generation will be covered.ET 449

CNC LATHE OPERATIONS: O.D. TURNING and External Threading

LABORATORY 3

Objectives: After completing this exercise you should be able to perform the following:

1. Import an IGES file into OneCNC

2. Edit the file for delineating required geometry

3. Set the coordinate system for the lathe operations

(lathe radius)

4. Select the geometry to be turned

5. Specify tooling information required

6. Modify cut control as necessary

7. Generate a tool path for the part specified

8. Post-process tool path for a HAAS lathe

9. Save the file as a PLAIN ASCII format

10. Download file to the HAAS TL-1 lathe

11. Run the program (under supervison) and produce

the required part.

Procedures:

Prior to using OneCNC, create a model or 2D drawing of part shown in the following section. You may create the geometry using a 3D package of your choice (i.e. ProE, ProD) or create using AutoCad or equivalent.

Steps necessary for creating a toolpath are provided with graphical

illustrations .

Major steps include the following:

STEPS: ET 449 Lathe 3D Model Import Method

1. Create 3D parametric model. Make sure 0,0,0 is located on the

right end, at center.

2. Export IGES file

3. Open OneCNC Lathe Professional

4. Import IGES file

5. From the menu, select MODEL: Extract Lathe Profile

6a. A blue outline will be generated representing the lathe profile

6b. For facing, the line show must be broken and trimmed so facing

will only occur from the center of the part outward (radius).

7. From the Edit menu, select Break, Divide and click on the like as shown in step 6.

Note: Select the number of divisions = 2.

8. Trim the “bottom” half of the line as shown below:

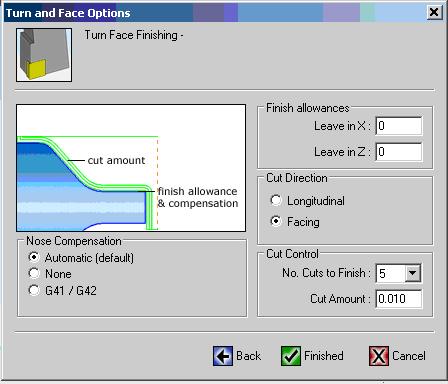

9. Select Lathe Toolpaths and pick Turn/face finishing

10. Select the line as indicated below for facing, then select end point.

11. Select the tool (for this lab we will use a VNMG 35 degree) tool.

Station should be 5 and tool offset should be 5. Select coolant none

and Work Offset to G54

Specify feed rate for inches/rev between .003 and .005. Select

RPM, Spindle speed = 1000 to 1400 RPM (for acetyl).

12. Enter values as show for facing operation, then click Next.

13. Enter values as shown in the final dialogue window for the facing

operation.

You should now have a toolpath for the facing operation:

14. Create a ROUGHING operation:

15. Next Pick the profile geometry for the roughing operation as shown

below then right mouse click to select (use the same VNMG tool #5).

16. Enter the values as show on the next two dialogue windows, then

click Finished.

17. You should have a toolpath similar to the one shown below:

18. Next Create a Threading toolpath: Select External Threading

from the menu as shown:

19. Next select the line for the thread geometry as shown:

20. Enter the information in the dialogue windows as shown (note enable

editing

and change the tool information as indicated (change tool angle to

60 deg.)

21. Click Accept and verify tooling information is as shown below:

22. On the next screen, enter the information as shown below:

23. Click NEXT, then click FINISHED. You should see a backplot

of the toolpath

similar to the one shown below:

24. Click on NC Manager and select PREVIEW TOOLPATHS. Make sure

TOOLPATH GROUP is highlighted.

25. You should see a series of tool paths generated on the screen similar

to the ones

shown below:

FACING

ROUGHING

THREADING

26. You are now ready to post process: Make sure HAAS is the post

processor

selected prior to posting as shown: After posting, the file is

ready for download to the HAAS SL20 CNC lathe.

27. You may also want to print a JOB SHEET as depicted below:

JOB SHEET (Toolpath Group #1)

Post Used - Haas

Post Date - Sunday, January 28, 2007 (17:34)

Time to Machine - 25 minutes 52 seconds

Filename - C:\Documents and Settings\ball\Desktop\Lab3.igs

Part Number -

Program Number - 0000

Time of Creation - Sunday, January 28, 2007 16:16

Last Modified - Sunday, January 28, 2007 16:16

System Used - OneCNC-XR2 Lathe Professional - Version 7.33

Author - Default

Notes - None

OPERATIONS

Total number of operations - 3

Operation #1 (1:Lathe Turn Finish)

Operation time - 1 minutes 8 seconds

Tool - Station #5 : OD Finish Right 35 Deg (Turn/Face, 0.38 Dia, 0.00

Tip, F0.005, S1000 RPM)

Operation #2 (2:Lathe Turn Rough)

Operation time - 15 minutes 53 seconds

Tool - Station #5 : OD Finish Right 35 Deg (Turn/Face, 0.38 Dia, 0.00

Tip, F0.002, S1200 RPM)

Operation #3 (3:Lathe Thread External)

Operation time - 8 minutes 51 seconds

Tool - Station #8 : OD Thread Right 60 deg (Thread, 0.30 Dia, 0.00

Tip, F0.1, S100 RPM)

The following part will be produced on a HAAS CNC lathe.

Threads can be produced in several different manners using CNC machine

tools. Some of these methods include:

A good introduction to threads and fastners can also be found at the following websites:http://www.mech.uwa.edu.au/DANotes/threads/intro/intro.html

http://www.jjjtrain.com/vms/cutting_tools_hand_tap.html#1

Threads can be produced in several different manners

using CNC machine tools. Some of these methods include:

THREAD MILLING: NOTE THAT CUTTER MOVES IN A HELICAL PATH. Any CNC having helical interpolation can cut threads