Feedrate = 10 ipm RPM = 2500

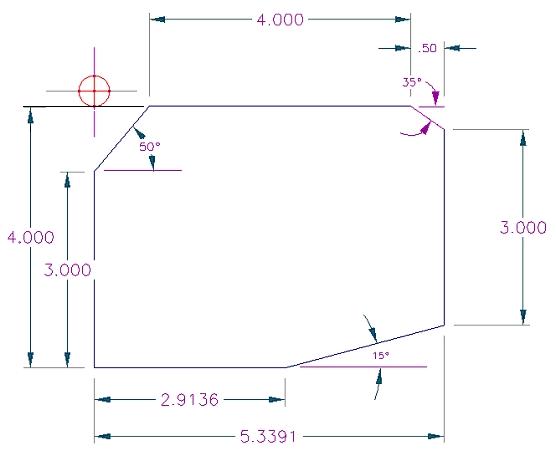

Diagram showing target tool path points.

Introduction

Syllabus

Scope of Course

CNC Basics

Coordinate systems and positioning

methods

NC "Words"

X, Y, Z

F

S

Basic G & M codes

ASSIGNMENTS

Controller Layout

Navigating through MENUS

AutoEdit Software

Lab 2 Prep work

Fixturing and Tooling considerations

Set Up Sheets and Operator Procedures

HAAS VF-1 Introduction

Controller

Layout

Navigating through MENUS

Setting Workplanes G54

Setting Tool Offsets

Manual

calculations for contouring

Trigonometric Functions

Determining Cutter Compensation

Cutter Compensation Methods

Introduction to Lab 3

Complete the following problem for homework.

1. Show all calculations

2. Develop required CNC code

3. Simulate tool path in AutoEdit

4. Screen capture simulation graphic

5. Turn in calculations, CNC program listing,

Graphic of tool path

NOTE: Procedures for doing manual calculations

will be explained today, and some of the X,Y coordinates will be determined.

Take good notes!

Part to be machined: Cutter: 3/8 Diameter.

Z depth of cut = .1875

Feedrate = 10 ipm RPM = 2500

Diagram showing target tool path points.

FEEDS AND SPEEDS

There are many variables that

affect the speed and feed rates, including:

Type of material

Hardness of material

Condition of material

Type of tool material

Geometry of Tool

Type of Machining Operation

Rigidity of Machine

Rigidity of Setup

Type of Coolant

In general, referenced speeds

and feed data are for beginning points. Adjustments

may be necessary to compensate

for the variables above. Make sure referenced

data matches the type of operation

and variables show above as closely as possible.

NOTE: Referenced Speeds are for HHS and only

recommended starting values:

MATERIAL

SFPM

Aluminum and Alloys 200- 300 FPM

Brass

150- 300 FPM

Bronze

200-250 FPM

Cast

Iron

30 (hard) to 150( soft) FPM

Magnesium

300 - 600 FPM

Steel,

Alloy

30 - 90

Steel, Low Carbon

90-120

NOTE: A MORE DETAIL CHART CAN BE FOUND AT THE FOLLOWING

WEBSITE: http://www.lexcut.com/catalog/FEEDS-SPEEDS.PDF

A TROUBLESHOOTING GUIDE CAN BE FOUND AT

THE FOLLOWING: http://www.lexcut.com/technical-support.html

Note: General rule

of thumb: Depth of cut should never exceed the radius of the cutter.

SPEED AND FEED RATE CALCULATIONS:

RPM: GENERAL FORMULA:

RPM = CS / CIRCUMFERENCE

ENGLISH: RPM = FT. x 12 in.

x 1 REV

Min.

Ft

p D

METRIC: RPM = m

x 1000 mm x 1 REV

min.

m p

D

NOTE: D = DIAMETER:

FOR TURNING, D = DIAMETER OF STOCK

FOR DRILLING, REAMING, MILLING, D = DIAMETER OF TOOL.

FEED RATES:

TURNING: Refer to Tables for Turning:

MATERIAL

ROUGHING

FINISHING

Cast

Iron

.010 -

.020

.003 - .006

Low Carbon Steel .010 -

.020

.003 - .005

Hi Carbon Steel .008 -

.020

.003 - .005

(annealed)

Alloy

Steel

.005 -

.020

.003 - .005

(normalized)

Aluminum

.015 - .

030

.005 - . 010

Bronze & Brass .010 -

.020

.003 - .010

General Recommendation for low carbon steel: .007 -.010 in. per revolution

(.25 - .4 mm/rev)

is used for roughing. Finishing feeds are .001 - .003 in. per

revolution (.07 - .12 mm/rev)

MILLING: Fr = N x T x RPM

where: N = Number of Teeth

Fr = Feed rate in IPM (or mm per minute for metric)

T = Feed per Tooth per Revolution

RPM = Revolutions per minute = CS/Circumference

MACHINING TIME:

LATHE: MT = LENGTH / (FEED X RPM); MT = L / (F X N)

MILL: MT = LENGTH / (FEED RATE); MT = L / ( fr )

MAKE SURE APPROPRIATE TABLES ARE CONSULTED FOR MATERIAL

AND CUTTING TOOLS BEING USED.

NOTE: THERE ARE TWO TYPES OF MILLING:

UP MILLING (CONVENTIONAL MILLING) - Chips are carried

away from the base stock.

Down Milling (Climb Milling) - Chips are carried into the base stock.

In general,

UP Milling is recommended for older equipment and lower horsepower

machine

tools, and less rigid setups. In climb milling there is a tendency

for the cutter

to

"climb over the work" if the setup is not rigid.

CLASSES OF STEEL

STEEL: PLAIN CARBON

LOW: .10 - .30 % C MEDIUM: .30 - .60 % C HIGH .60 - 1.7% C

ANSI - SAE DESIGNATIONS: 4+ CHARACTERS

(e.g. 1018: first 2 digits classification, last 2 digits %

carbon in hundredths)

x's = % C in hundreths e.g. 10 = .10% Carbon

CARBON STEELS : CLASS [ 1 ]

10xx

Plain Carbon

11xx

Free Cutting Resulfurized

13xx

Manganese

NICKEL STEELS: CLASS [2]

20 xx

.5 % N

21xx

1.5% N

23xx

3.5% N

25xx

5.0% N

CORRISION & HEAT RESISTING: CLASS [3]

303xx

(example)

MOLYBDENUM: CLASS [4]

41xx

Chrominum

43xx

Chrominum Nickel

46xx & 48xx Nickel

CHROMIUM: CLASS [5]

50xx

Low

51xx

Medium

52xx

High

CHROMIUM-VANADIUM: CLASS [6]

6xxxxx

(example)

TUNGSTEN: CLASS [7]

7xxx

(example)

TRIPLE ALLOY: CLASS [8]

8xxx

(example)

SILICON MANGANESE: CLASS [9]

9xxx

(example)

LEADED: NOTE: "L" INDICATES LEADED

11Lxxx

(example)

CLASSIFICATIONS OF ALUMINUM

CODE MAJOR ALLOYING ELEMENT

1xxx

None

2xxx

Copper

3xxx

Manganese

4xxx

Silicon

5xxx

Magnesium

6xxx

Magnesium & Silicon

7xxx

Zinc

8xxx

Other Elements

LETTER DESIGNATIONS:

F As

Fabricated

O

Annealed

Softest Temper

H

Strain

Hardened

H1 Strain Hardened Only

H2 Strain Hardened and

Partial

Anneal

H3 Strain Hardened and

Stabilized

EXTENT OF HARDESS

2 1/4 Hard

4 1/2 Hard

6 3/4 Hard

8 Full Hard

9 Extra Hard

EXAMPLE: 5056-H18

50 Aluminum Magnesium Alloy

56 .56 pure Aluminun

H1 Strain Hardened

8 Full Hard Temper

WEEK 5

Introduction

to ONECNC

Procedures

for importing files

Steps in

creating CNC operations

2D vs. 3D

machining

3D Models

to 2D Engineering Drawings

Importing

files to OneCNC

Manipulating

Files for CNC

Postprocessing

Files

Transferring

Files to CNC Machines

Verifying

Machined Geometry

Contouring

Pocketing

Drilling

Verifying tool paths

Post

processing procedures

Fixturing and Tooling considerations

Set Up Sheets and Operator Procedures

HAAS VF-1 Introduction

Controller

Layout

Navigating through MENUS

Setting Workplanes G54

Setting Tool Offsets

File Importing

Graphical Simulation

IN CLASS DEMO OF ONECNC

ONECNC: PROCEDURES AND TUTORIAL (LAB 4)

ONECNC: PROCEDURES FOR IMPORTING GEOMETRY

FROM EXTERNAL SOURCES AND TOOLPATH GENERATION FOR A VALV

BODY PART (LAB 5)

MID-TERM EXAM REVIEW

STUDY GUIDE:

1. Be familiar with commonly used G codes; be able to define and recognize.

2. Be familiar with commonly used M codes: be abel to define and recognize.

3. Know coordinate and positioning systems used in CNC milling operations.

4. Be able to calculate:

Feed Rates

RPM

Cutting Speeds

Material removal rates

5.

Be able to determine the toolpath required for producing a piecepart by

calculating cutter compensation (manually). Note review your trig!

6. Be familiar with the general procedures and specifically the following operations in OneCNC:

Pocketing;

Contouring;

Drilling

10. Be able to complete required information (in example dialog boxes) for the above operations.

11. Be familiar with the procedures for importing DXF files into OneCNC

12.

Know the various classifications of metals and be prepared to intrepret

the meaning (e.g. 1018 Steel

or 6061-T6 aluminum.

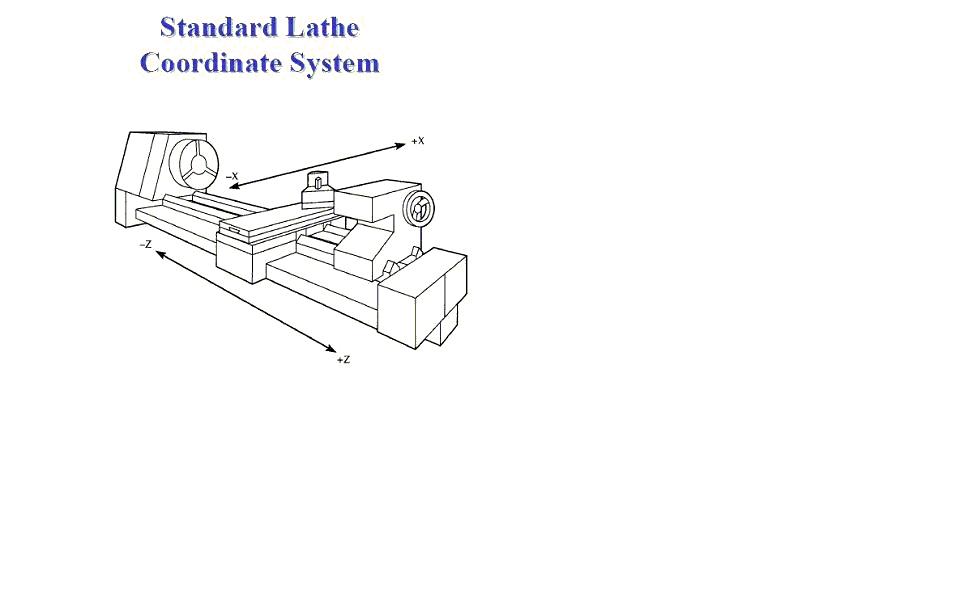

13. Be familiar with ANSI standards for cutting tool inserts.

14. Be familiar the the geometric shapes of commonly used inserts.

15. Be able to sketch a piece part given the CNC code.

16. Know the difference between climb and conventional milling

17. Be able to describe which is preferrable when machining with carbide inserts and why.

18. Be famililar with workplane and tool offsets (HAAS machine)

19. Be familiar with general layout of the HAAS controller (revisit the HAAS website for review)

20. Be able to create a set-up sheet for a piece part

Week 10: MID TERM TEST RETURN AND Work on Aluminum Wallet Designs

Week 11: Production Systems

AUTOMATED MANUFACTURING SYSTEMS

TOPICS:

1. AUTOMATED

SYSTEMS

2. PRODUCTION

OPERATIONS

3. EXAMPLE

PROBLEM

4. HOMEWORK

ASSIGNMENT

5. Project

Discussion & Plan time

DEFINITION OF AUTOMATION: APPLICATION OF MECHANICAL, ELECTRONIC AND COMPUTER BASED SYSTEMS TO OPERATE AND CONTROL PRODUCTION.

FOR THIS COURSE, AUTOMATION WILL BE CONSIDERED AS PERTAINING TO:

PROCESSING

ASSEMBLY

MATERIAL HANDLING

INSPECTION

CIM DEALS WITH THE INFORMATION & SUPPORT OF PRODUCTION

CAD

CAM

CAE

CONTROL

HOW CAN AUTOMATION BE A SUCCESS?

PRODUCT IS STABLE

DESIGNED FOR A SPECIFIC PRODUCT (OR FAMILY)

IS PLANNED AND FLOW IS ANALYZED

SYSTEM IS CAPABLE

SYSTEM IS RELIABLE

ADAPTABLE TO CHANGES IN CUSTOMER NEEDS

TYPES OF PRODUCTION SYSTEMS:

JOB SHOP - LOW VOLUME HIGHLY FLEXIBLE

BATCH - MEDIUM VOLUME ADAPTABLE

MASS - HIGH VOLUME NOT FLEXIBLE

LAYOUTS:

FIXED POSITION - LARGE PRODUCTS (MUST MOVE OPERATIONS TO PRODUCT)

PROCESS - MACHINES ARRANGED AND GROUPED BY TYPE OF PROCESSING

PRODUCT

- MACHINES ARRANGED TO ACCOMMODATE A SPCIFIC PRODUCT OR FAMILY

(FLOW PROCESSING).

Manufacturing Production Systems

TERMS:

Transfer Line

Flexible Manufacturing Systems

Job Shop

Process Layout

Product Layout

Cellular Layout

INTRODUCTION

As a greater demand for a larger variety of products grows, and the increase in global competition for world markets increases, the efficiency in design, production, and delivery becomes critical for the survival of manufacturing firms. Flexibility has become the key ingredient for success and has been possible largely due to advances in computer technology. In this module we will begin with a broad overview of the functions of CAD, CAM, and Manufacturing followed by the comparison of production systems, and finally, an introduction to programmable automation. This topic will be the focus for the remaining class meetings and will deal primarily with control at the machine and workstation level.

Production Systems Overview: In its basic form, a production

process is simply a system that converts raw materials into useful

products. Usually the system approach is either changing the properties

of a raw material or combining different components to make a final product

that is acceptable to the customer. However the manufacturing cycle,

coordination of data, and system control can become complex across different

types of production systems.

Two main factors must be established before a firm can gain significant

ground in picking up a share of the market and remaining competitive.

Efficiency and Flexibility. In other words, the raw materials

must be available in time (theoretically no sooner or no later than needed)

and flexibility to rapidly change production from one product to another

must be in place. The greatest influence in how these factors come

about in the integration of computers for design (CAD) manufacturing,

(CAM) and control (e.g. CNC and PLC). CAD to CAM to Manufacturing.

The basic functions are shown below:

CAD

Engineering Documentation

Process Requirements

Material Requirements & FEA

Testing and Simulation

CAM

PRODUCTION SYSTEMSProduction Engineering

Tool Design

NC/Control

Process Planning

GT PlanningManufacturing Engineering

Scheduling and Control

Production PlanningQuality Engineering

Process Capability

ReliabilityMANUFACTURINGFabrication

Assembly

Quality Assurance

Production and System Control

Production systems are classified by the arrangement of departments and processing within manufacturing facilities. While many variations can exist, typically there are three major classifications including: 1) Job Shop, 2)Batch Production, and 3) Mass Production. A brief overview along with advantages and disadvantages will be presented.

Job Shop. This type of system is highly customized and produces many different types of products, with very low volume for a given product. A variety of general purpose equipment is used in this environment. Generally speaking, a high degree of skill is required of operators. Machines are typically grouped by type and is referred to as process layout.

A job shop can produce a wide variety of products however, scheduling becomes very difficult to manage from a flow stand point. To give an example of how things can get complicated in a hurry, consider m number of parts being routed through n number of machines. Suppose there are 4 different parts that must be routed through 8 machines. The possible sequences of routing becomes mn or 4 8 = 65,536 possible sequences. It is quite easy to see how this can be a scheduling nightmare.

Batch Production. When products are manufactured in limited quantities, it is referred to as batch production. This type of system is more suited for intermediate size quantities, but those that are not sufficient to warrant a dedicated production line per product. Typically the production capacity is greater than the demand, and products are produced then stored in inventory. Safety stock levels are generated to meet the current and future demand, then production is switched to the next item to be produced to meet scheduling demand. Production equipment and processing machines in a batch environment are more specialized than the job shop. However; the skill level required is decreased. Varying levels of automation exist, and typically machines are arranged in a manner to conform to the products. This type of layout is called product layout.

Mass Production. The mass production system is strictly for

high volume and virtually no flexibility. A production line or even

an entire plant is dedicated to producing only one product. Hard

automation is employed since no changeover is required. Mass production

is capital intensive and requires specialized tooling, jigs, and fixtures.

A high and constant demand is a must for mass production to pay for the

capital invested. Work is moved between stations, and the production

line is balanced to maximize the rate of production. Labor skills

are reduced to a minimum, making work on an assembly line repetitious.

Thus the workstations are good candidates for automation. Two common

terms associated with mass production are assembly line and flow line.

In assembly line production systems workstations are sequential, and parts

are usually moved using conveyors or high speed material handling equipment.

Flow line production is usually associated with processes that are continuous

such as paper, petro-chemicals or continuous casting steel mills.

FMS. Across all manufactured goods, batch production is by far the most prevalent. It has been estimated that 95% of all manufactured goods are produced in lot sizes less than an average of 50 parts. Obviously processes layout cannot accommodate high volume, and mass production is not capable of quick changeover. Therefore, cellular or flexible manufacturing systems are require. In this type of system, machines are arranged in a manner to accommodate a "family" of parts within a given group. This is called group technology. By processing similar parts through a cell, set-up times are reduced and throughput times improved. Duplication of equipment and tooling is also reduced.

The diagram shown below illustrates a comparison of job shop, FMS and transfer lines with respect to volume and flexibility.

GOALS:

1.

DEVELOP UNDERSTANDING OF TERMS AND MODELS COMMON TO MFG. SYSTEMS

2. SHOW HOW MODELS CAN BE USED TO EVALUATE SYSTEMS

TERMS STRIVE TO

MLT DECREASE

U INCREASE

PC INCREASE TO COMFORT ZONE (AROUND 95 %)

WIP DECREASE

TIP

DECREASE

MATHEMATICAL MODELS - ASSUME BATCH PROCESSING OF Q PARTS

MANUFACTURING LEAD TIME

MLT IS THE TOTAL TIME TO PROCESS PARTS THROUGH THE PLANT.

nm

MLT

= S

[ Tsui

+ QToi

+ Tnoi]

i = 1

For varying set-up, processing and non-operational times, the average can

be used:

___ __ ___

MLT

= nm [ Tsu + QTo + Tno]

For flow type operations (assuming synchronized):

MLT

= nm (TTR + To Longest)

FOR BATCH PROCESSING:

PRODUCTION TIME:

TP = (TSU + QTO) / Q conceptually TIME / QUANTITY e.g. hrs./piece

PRODUCTION RATE: conceptually QUANTITY / TIME e.g. pices/hr.

RP = QUANTITY / TIME = 1 / TP

PLANT CAPACITY (PC)

PC =[ W (work centers) X SW (shifts/wk x H hours/shifts) x RP (rate of production) ] / nm

UTILIZATION U=OUTPUT / CAPACITY

WORK IN PROCESS (WIP) = [(PC x U / (SW x H)] x MLT

WIP RATIO = WIP / # MACHINES PROCESSING

TIP RATIO = MLT / (nm x To)

= Time to Produce / Actual Operational Time

EXAMPLE INCLASS PROBLEM:

An

average of 20 new orders are started through a certain factory each

month. On average, an order consists of 50 parts to be processed

through 10 machines in the factory. The operation time per

machine for each part = 15 minutes. The nonoperation time per

order at each machine averages 8 hours, and the required setup time per

order is 4 hours. There are 25 machines in the factory, 80% of

which are operational at any time (the other 20% are in repair or

maintenance). The plant operates 160 hours per month.

However, the plant manager complains that a total of 100 overtime

machine-hours must be authorized each month in order to keep up with

the production schedule. Determine the following:

A. What is the manufacturing lead time for a average order?

B. What is the plant capacity (on a monthly basis) and why must overtime be authorized?

C. What is the utilization of the plant?

D. Determine the average level of work-in-process (number of parts-in-process) in the plant.

Solutions:

___

__ __

A. MLT = nm(Tsu + QTo + Tno)

= 10(4 hr + (50 x .25 hr) + 8 hr)

= 245 hours per order.

B. Tp = (Tsu + QTo) / Q = (4 + (50 x .25))/50 = .33 hr./pc

Rp = 1/Tp = 1 / .33 hr/pc = 3.0303 pc/hr.

PC = (Workcenters x Availability x hours/month x Rp) / nm

= (25 x .8 x 160 hrs/month x 3.0303 pc/hr)/10 = 969.7 pc/month

Note: Parts scheduled/month = 20 x25= 1000 pc/month

Schedule exceeds PC by 1000-969.7 = 30.3 parts

Overtime Required = (30.303 pc x 10 machines) / 3.0303 pc/hr =100 hr.

C. U = (1000 pc / 969 pc) = 1.03125 = 103.125%

D. WIP = [(PC x U / HR)] x MLT

= [(969.7 pc/mo. x 1.03125)/ 160 hr/mo] x 245 hr. = 1531.25 pieces

HOMEWORK: Due next Monday.

1.

A certain part is routed through six machines in a batch production

plant. The setup and operation times for each machine are given

belwo. The batch size is 100 and the average non-operational time

per machine is 12 hours. Determine both the MLT and Rp for

operation number 3.

Machine

Setup

(hrs)

Operation time (min.)

1

4

5.0

2

2

3.5

3

8

10.0

4

3

1.9

5

3

4.1

6

4

2.5

2.

Suppose the part in the previous problem is made in very large

quantities on a production line in which an automated work handling

system us used to transfer parts between machines. Transfer time

between stations = 15 seconds. The total time required to set up

the entire line is 150 hours. Assume that the operation times at

the individual machines remain the same as shown in the table

above. Determine: A. The MLT for a part coming off

the line, B) Production rate for operation 3, C) The Theoretical

production rate for the entire production line.

3.

The average part produced in a certain batch manufcturing plant must be

processed through an average six machines. Twenty new batches of

parts are launched each week. Average operation time = 6 minures;

Average Setup time = 5 hours, average batch size = 25 parts, and

average nonoperation time per batch = 10 hours per machine. There

are 18 machines in the plant. The plant operates an average of 70

production hours per week. Scrap rate is negligible.

Determine the following:

A. Manufacturing Leat Time (MLT)

B. Plant Capacity (PC)

C. Plant Utilization (U)

D. Explain the relationship of nonoperational time and the effect on plant utilization.

Week 12:

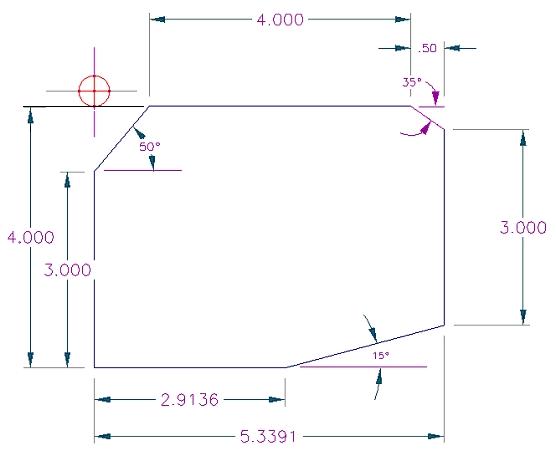

Introduction to CNC Lathe Operations

CNC turning centers,

commonly know as CNC lathes also the Cartesian Coordinate system for

programmed coordinates. However, the axes are different compared

to milling. Only the X and Z axis are used for turning such that

the Z axis represents the center of the spindle and X represents the

tool direction of movement. The diagram below shows the axes for

CNC lathe work.

Objectives: After completing this exercise you should be able to perform the following:

1. Import an IGES file into OneCNC

2. Edit the file for delineating required geometry

3. Set the coordinate system for the lathe operations

(lathe radius)

4. Select the geometry to be turned

5. Specify tooling information required

6. Modify cut control as necessary

7. Generate a tool path for the part specified

8. Post-process tool path for a HAAS lathe

9. Save the file as a PLAIN ASCII format

10. Download file to the HAAS TL-1 lathe

11. Run the program (under supervison) and produce

the required part.

Procedures:

Prior to using OneCNC, create a model or 2D drawing of part shown in the following section. You may create the geometry using a 3D package of your choice (i.e. ProE, ProD) or create using AutoCad or equivalent.

Steps necessary for creating a toolpath are provided with graphical

illustrations .

Major steps include the following:

STEPS: ET 349 Lathe 3D Model Import Method

1. Create 3D parametric model. Make sure 0,0,0 is located on the

right end, at center.

2. Export IGES file

3. Open OneCNC Lathe Professional

4. Import IGES file

5. From the menu, select MODEL: Extract Lathe Profile

6a. A blue outline will be generated representing the lathe profile

6b. For facing, the line show must be broken and trimmed so facing

will only occur from the center of the part outward (radius).

7. From the Edit menu, select Break, Divide and click on the like as shown in step 6.

Note: Select the number of divisions = 2.

8. Trim the “bottom” half of the line as shown below:

9. Select Lathe Toolpaths and pick Turn/face finishing

10. Select the line as indicated below for facing, then select end point.

11. Select the tool (for this lab we will use a VNMG 35 degree) tool.

Station should be 5 and tool offset should be 5. Select coolant none

and Work Offset to G54

Specify feed rate for inches/rev between .003 and .005. Select

RPM, Spindle speed = 1000 to 1400 RPM (for acetyl).

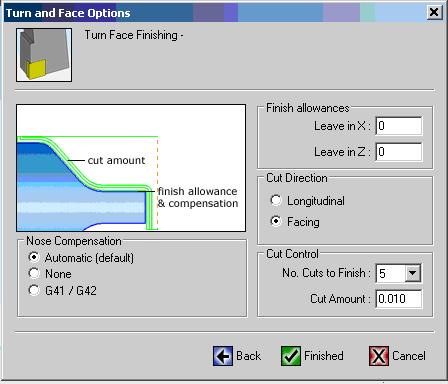

12. Enter values as show for facing operation, then click Next.

13. Enter values as shown in the final dialogue window for the facing

operation.

You should now have a toolpath for the facing operation:

14. Create a ROUGHING operation:

15. Next Pick the profile geometry for the roughing operation as shown

below then right mouse click to select (use the same VNMG tool #5).

16. Enter the values as show on the next two dialogue windows, then

click Finished.

17. You should have a toolpath similar to the one shown below:

18. Next Create a Threading toolpath: Select External Threading

from the menu as shown:

19. Next select the line for the thread geometry as shown:

20. Enter the information in the dialogue windows as shown (note enable

editing

and change the tool information as indicated (change tool angle to

60 deg.)

21. Click Accept and verify tooling information is as shown below:

22. On the next screen, enter the information as shown below:

23. Click NEXT, then click FINISHED. You should see a backplot

of the toolpath

similar to the one shown below:

24. Click on NC Manager and select PREVIEW TOOLPATHS. Make sure

TOOLPATH GROUP is highlighted.

25. You should see a series of tool paths generated on the screen similar

to the ones

shown below:

FACING

ROUGHING

THREADING

26. You are now ready to post process: Make sure HAAS is the post

processor

selected prior to posting as shown: After posting, the file is

ready for download to the HAAS SL20 CNC lathe.

27. You may also want to print a JOB SHEET as depicted below:

JOB SHEET (Toolpath Group #1)

Post Used - Haas

Post Date - Sunday, January 28, 2007 (17:34)

Time to Machine - 25 minutes 52 seconds

Filename - C:\Documents and Settings\ball\Desktop\Lab3.igs

Part Number -

Program Number - 0000

Time of Creation - Sunday, January 28, 2007 16:16

Last Modified - Sunday, January 28, 2007 16:16

System Used - OneCNC-XR2 Lathe Professional - Version 7.33

Author - Default

Notes - None

OPERATIONS

Total number of operations - 3

Operation #1 (1:Lathe Turn Finish)

Operation time - 1 minutes 8 seconds

Tool - Station #5 : OD Finish Right 35 Deg (Turn/Face, 0.38 Dia, 0.00

Tip, F0.005, S1000 RPM)

Operation #2 (2:Lathe Turn Rough)

Operation time - 15 minutes 53 seconds

Tool - Station #5 : OD Finish Right 35 Deg (Turn/Face, 0.38 Dia, 0.00

Tip, F0.002, S1200 RPM)

Operation #3 (3:Lathe Thread External)

Operation time - 8 minutes 51 seconds

Tool - Station #8 : OD Thread Right 60 deg (Thread, 0.30 Dia, 0.00

Tip, F0.1, S100 RPM)

The following part will be produced on a HAAS CNC lathe.

See your lab instructor for assistance in setting up the TL 1.

Machine the part.

Write a report using the standard format.

Threads can be produced in several different manners using CNC machine

tools. Some of these methods include:

A good introduction to threads and fastners can also be found at the following websites:http://www.mech.uwa.edu.au/DANotes/threads/intro/intro.html

http://www.jjjtrain.com/vms/cutting_tools_hand_tap.html#1

Threads can be produced in several different manners

using CNC machine tools. Some of these methods include:

THREAD MILLING: NOTE THAT CUTTER MOVES IN A HELICAL PATH. Any CNC having helical interpolation can cut threads

The next laboratory exercise will cover the steps in producing an

external thread on a CNC lathe.

Purpose: This exercise will cover the basic procedures for Outside Diameter (O.D.) turning and external threading operations in SurfCam. File importing, coordinate systems, CNC options, tool selection, and toolpath generation will be covered.ET 349

CNC LATHE OPERATIONS: O.D. TURNING and External Threading

LABORATORY 7

Objectives: After completing this exercise you should be able to perform the following:

1. Import a dxf file into SurfCam

2. Edit the file for delineating required geometry

3. Set the coordinate system for the lathe operations

(lathe radius)

4. Select the geometry to be turned

5. Specify tooling information required

6. Modify cut control as necessary

7. Generate a tool path for the part specified

8. Post-process tool path for a HAAS lathe

9. Save the file as a PLAIN ASCII format

10. Download file to the HAAS TL-1 lathe

11. Run the program (under supervison) and produce

the required part.

Procedures:

Prior to using SurfCam, create a model or 2D drawing of part shown in the following section. You may create the geometry using a 3D package of your choice (i.e. ProE, ProD) or create using AutoCad or equivalent.

Steps necessary for creating a toolpath are provided with graphical

illustrations .

Major steps include the following:

STEPS:

1. Create DXF

2. Edit and

remove non-essential lines

3. Delete all geometry below the Center Line (C.L.) of the part.

4. Change coordinate system to LATHE RADIUS

5. Move object so that 0,0 is located at the right, C.L. of the part

6. Select NC Lathe

7. Select Turning Option

8. Select geometry to be machined

9. Click DONE and edit tool information

10. Edit Cut Control and turn on undercut

11. Select RETRACT AND CLEARANCE

12. Select OD geometry for threads to be cut

13. Select Threading Tool

14. Edit cut control and select R.H. threading

15. Specify RETRACT AND CLEARANCE

16. Save and transfer to HAAS

17. Produce Part (will assistance from lab instructor)

18. Write lab report and submit

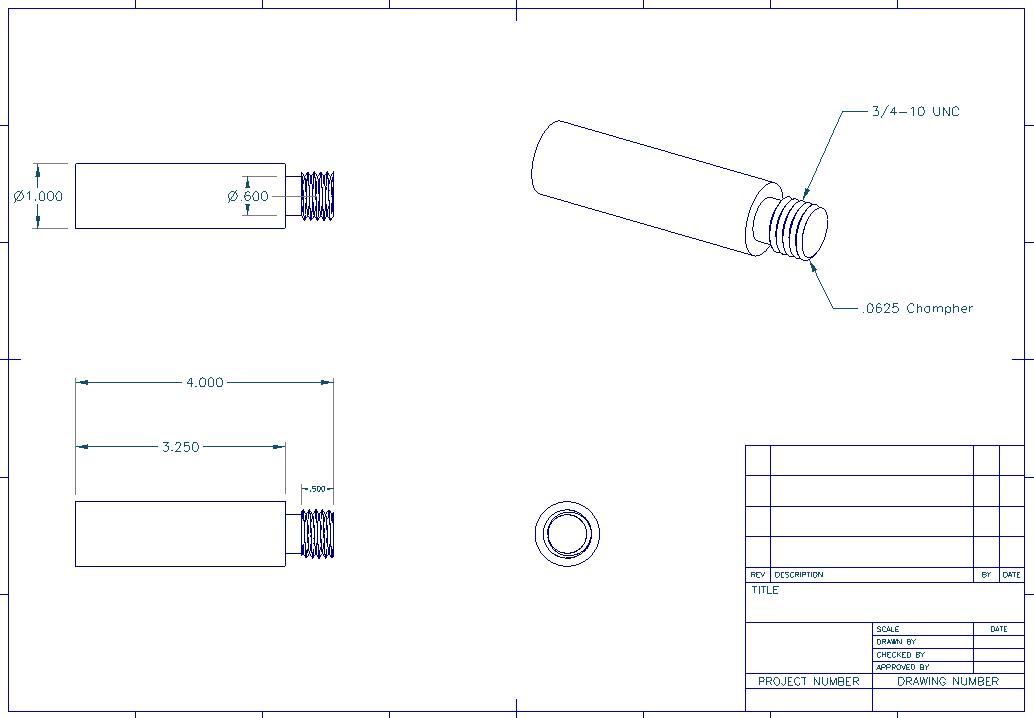

The following part will be produced on a HAAS CNC lathe.

NOTE: Thread Specification: 3/4 -10, UNC, Class 2

Major Diameter: .748

Minor Diameter: .625

Thread Depth: .0615 Depth = (Major

- Minor) / 2

Feed Rate: General Approximation: 1/n or F = P In

this

case F = .1 IPR

3D - MODEL

ENGINEERING DRAWING : EXPORT AS DXF