ET 349 Rapid Prototyping and Tooling:ASSIGNMENTS

ASSIGNMENT 1 (BEGIN IMMEDIATELY)

REVIEW AND STUDY THE SAFETY RULES GIVEN IN

LABORATORY 1. SIGN AND TURN IN THE

LAB SHEET TO YOUR LAB INSTRUCTOR. THIS

IS YOUR TICKET TO ENTER THE MACHINING

LABORATORY!

Visit the HAAS web site and review the section on the HAAS controller.

http://www.haascnc.com/solutions_control.asp#controlBECOME FAMILAR WITH THE HAAS MACHINE TOOL AND CONTROLLER!

Download a copy of the HAAS G & M codes for your personal reference.

http://www.haascnc.com/training/MillProgram_PDF/xMGMCard.pdf

1. Study the drawing shown in Figure 1, and identify

the maximum machineable area for the work

part to be produced. Note that pre-sized stock

will be provided that conforms to the dimensions shown.

The first step for this lab exercise will be the creation

of a luggage tag. You have the choice of designing

the product as you wish within the constraints as follows:

The name plate must display WCU and ET

in some manner and fit within the allowable work space.

Since you will writing the program manually,

it is suggested that the layout be kept relatively simple.

There are two machining operations that must

be performed: 1) WCU and ET text; and 2) A drilled

1/8” hole to accept a chain, string, or strap for

mounting. Your layout design could look something

like what is shown in Figure 2.

2. Go to the following website and download a copy of the MACH3 CNC software (free for educational use in demo mode).

http://www.machsupport.com/downloads.php

Use the following STANDARD TEMPLATE

for your first manual CNC program.

%3. Visit the following websites and become familiar with the HAAS controller. Study each section so that you

O0001 (Program Name)

N05 G20 G40 G49 G54 G80 G90 G98

N10 M06 T01

N15 G43 H01

N20 M03 S1200

N25 G00 X0.0 Y0.0 (M08)

N30 G00 Z.2

N35

N40 (PLACE CODE HERE)

N45

N50

N97 G91 G28 Z2.0

N98 M05

N99 M30

%

http://www.haascnc.com/solutions_control.asp#control

ASSIGNMENT 3

1. Study the drawing shown in Illustration 1,

and identify the geometry to be machined. Note that pre-sized

stock will be provided by the lab instructor.

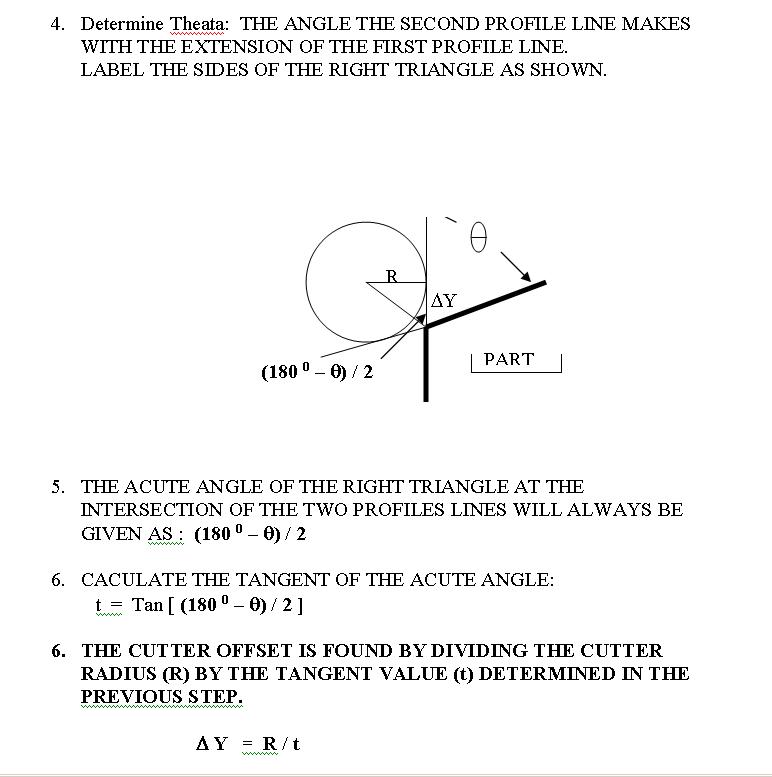

The first step for this lab exercise will determining tool path

coordinates. Tool path coordinates for

NORMAL lines (horizontal and vertical) can be found by offsetting

the part object lines by a value equal to the radius

of the cutter to be used. For this laboratory exercise,

a ¼ 4 flute end mill will be selected.

Illustration 1: Drill Index and Angle Gage

Develop a CNC program using AutoEdit software to

produce the provide of the part. See the illustration

below. You must calculate the offset and

machine tool coordinates for generating the toolpath (as

shown in green). A guide for calculating

coordinates is provided in the next section.

Calculate the coordinate values for the lines marked

as follows and record in the spaces provided below

(Note: attach a copy of manual calculations

as an appendix to the lab write up). Starting in the upper

left

hand corner of the part (0,0), determine the end point

of the first line (A). This coordinate will become the

beginning of line B. Continue CLOCKWISE around

the part and determine the endpoint coordinates for

each of the remaining lines and record below.

Download AUTOEDITNC and write the CNC code for Lab 3.

OPERATOR:____________________________ DATE:______

TIME:_____

PART NAME: VALVE BODY

PART # EX1

PART MATERIAL: 6061-T6 ALUMINUM

TOOL MATERIAL: M2 HSS

TOOL(S) TYPE: .5 " END MILL

TOOL # 10 COOLANT : FLOOD

PART ZERO LOCATION (upper right corner of part) WORK

PLANE: G 54

SPECIAL INSTRUCTIONS:

SETUP PROCEDURES:

1.

2.

3.

4.

5.

6.

.

.

.

N

INCLASS DEMO on ONECNC: Machining the part shown below (profiling,

pocketing, drilling, reaming)

RPM = CS x FT. x 12 in. x Rev

= 3.82 CS

Min FT

?D

D

Where: CS = Cutting Speed of the material in FEET PER MINUTE

D = Diameter of the cutter (or stock for lathe) in inches

Similarly, Feed Rate can be calculated as follows:

FR = FPT x t x RPM

Where: FPT = Feed per cutter tooth per revolution in thousandths

of a an inch

(English System).

t = Number of teeth on the cutter (no units)

RPM = Revolutions per minute of cutter.

How units cancel: FR (in/min) = in/tooth

x t (teeth) x Rev

Rev

Min

Today’s Notes on SurfCAM:

CAD Side: Used mainly for editing and manipulating drawings

CAM Side: NC - Used to create CNC tool paths

Verify – Produces a graphical simulation of tool path

POST - Post Processes code to machine executable format

General Steps for Producing CNC programs (2D):

1. Import DXF file

2. Strip unwanted text and geometry

3. Move to point (0,0) Note this is the G54 Workplane.

4. Select the geometry to be machined

5. Specify machining and set up information

6. Save file

7. Post-process

8. Save to 3 ½ floppy disk

9. Transfer to HAAS CNC Machine

1. SIGNED Safety Sheets should

be on file.

2. Lab 2 (Luggage Tag) should

have been completed.

3. Lab 3 (Drill Index should

be completed by September 20th, lab report due, September 25th).

4. Complete Lab 4 as soon as

possible (no machining of the actual part will be performed).

5. Complete Lab 5 as soon as

possible (afer lab 4). Again no actual part will be machined.

6. Drawings will be provided

for your semester project not later than Septemb er 25th.

7. Each lab group will be responsible

for setting up a production system to produce the steam engines

(one

for each class member, plus one extra for display).

Note:

You will be responsible for modeling parts, checking assemblies for tolerances,

fits, etc prior to

using the CAM software to produce any part. All parts much have complete

documentaion

including set-up sheets. You will NOT machine the part you produced,

but rater a team member

will machine the part from your specific documentation and instructions.

8. NOTE: We will complete

a ONECNC LATHE LAB simular to the same format as labs 4 and 5. However,

actual

parts will be machined in order to familarize you with the HAAS lathes.

9. The mid-term exam will be given

on October 9th.

10. The second half of the semester

we will focus on your project. Most laboratory work will be dedicated

to

project

work. Extra lab time will be provided.